Achieving a perfect, polished, laser-cut acrylic edge can be

a challenging task for even the most advanced laser users

because there are number of variables involved. You must

use a high-quality acrylic appropriate for your application;

determine the correct power, speed, and frequency settings;

and select a suitable lens and table configuration, just to

name a few. Below is a how-to guide to help any laser user

achieve a flame-polished edge when laser

cutting acrylic.

On Fire!

How to Achieve Flame-Polished Edges with Acrylic Processing

By Josh Stephens, Senior Applications Engineer, Trotec Laser

(Originally published in the October 2016 issue of Insights).

Achieving a perfect, polished, laser-cut acrylic edge can be

a challenging task for even the most advanced laser users

because there are number of variables involved. You must

use a high-quality acrylic appropriate for your application;

determine the correct power, speed, and frequency settings;

and select a suitable lens and table configuration, just to

name a few. Below is a how-to guide to help any laser user

achieve a flame-polished edge (FIGURE 1) when laser

cutting acrylic.

The removable lamellas above help prevent acrylic pieces, especially intricate ones like the letters shown, from moving or slipping during cutting.

FIGURE 1: A flame-polished edge lends any acrylic product a crafted,

high-end feel perfect for elevating recognition products and personal or

corporate gifts.

Material Preparation

First and foremost, achieving a flame-polished edge

depends heavily on the quality and type of acrylic being

cut. It’s important to have the correct materials before

attempting a flame-polished edge. Don’t be afraid to contact

your materials vendor or applications support personnel

from the company where you purchased your laser if you

have questions.

Many people ask me, “Prior to processing the acrylic,

should I leave the film on or off? What about paper

backing?” In general, you should leave the film on the

acrylic to protect the material during cutting. On the other

hand, if you are engraving or using small or thin parts,

you should take the film off to reduce the risk of flareups.

When processing acrylics with paper backing, at a minimum, you always should remove the paper from the

top side. However, it may be necessary to remove the paper

from both sides because the paper contains paraffin, which

causes flaming and reduces the cutting-edge quality.

Laser Power

As a general rule, more power yields better results. A

good rule of thumb for achieving a polished cut and good

production speed is to use 10 watts per 0.04 in. (1 mm).

Sixty watts can process ½ in. (12 mm); however, it will be

slower and the quality will be poorer. Your method also may

depend on your preferences. For example

- 400 watts for 1/8 in. (3 mm) = fastest speeds

- 400 watts for 1 in. (25 mm) = best quality

Frequency and Speed Settings

The correct frequency settings will depend on the material

you are using. You should start high on cast acrylic (10 to

20 khz) and lower on extruded (2 to 5 khz). Decreasing the

frequency means there will be fewer pulses, which results

in less energy in the material. This causes

- less flaming

- less boiling (which results from too much heat building in

the material)

- slower cutting speed

To achieve a flame-polished cut, you should set your speed

to less than 2/5 in./second (I suggest 600 mm/min.). For

best results on a separation cut, use maximum power and

maintain maximum frequency.

Lens and Focus

Determining which lens to use depends on the thickness of

the acrylic. For materials with a thickness of ¾ in. (20 mm)

or less, you should use the 2½-in. lens. For materials larger

than ¾ in. (20 mm), it is optimal to use a 5-in. lens with a

200- or 400-watt laser system.

Here are some best practices regarding focus:

- Defocusing results in better beam usage.

- Do not defocus when material is less than ¼ in. (6 mm).

- For materials larger than ¼ in. (6 mm), defocus 1/3 into

the material. (Example: Cutting ½ in. z-offset should be

-0.17 in.)

- Defocus if the cut edge is not straight or wavy lines

appear at bottom of the cut edge.

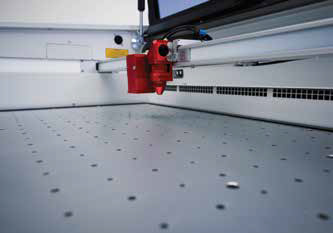

FIGURE 2: This worktable, used with a Speedy 400 laser, features

removable aluminum lamellas, which provide an excellent cutting surface for

most materials. However, when cutting acrylic, you may want to opt for acrylic

lamellas instead, which limit reflection of the laser.

Table Configuration

Your table configuration also should be determined

according to the size and thickness of the materials you

are processing. For parts larger than 4 in. (100 mm) or

thicknesses more than ¼ in. (6 mm), a cutting table with

acrylic lamellas (FIGURE 2) generally will produce the

best results. If you are processing parts smaller than 4 in.

(100 mm) or with thicknesses less than ¼ in. (6 mm), you

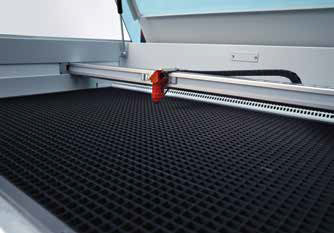

should use an acrylic grid on vacuum table (FIGURE 3) or a hard anodized cutting grid (FIGURE 4).

If you have a downdraft cutting table, you always should

make sure to cover any exposed working area to improve

suction beneath the acrylic. This is a key factor for better

results because it helps prevent air leaks and makes the

exhaust more efficient.

FIGURE 3: This vacuum table, used with a Speedy 300 laser, gently

fixes thin and lightweight materials to the worktable to prevent shifting during

processing. Adding an acrylic grid further helps prevent movement.

FIGURE 4: A hard cutting grid is ideal for most general cutting

applications because it helps keep even pieces smaller than 100 mm in a flat

position during and after cutting.

Exhaust and Gas

Exhaust plays a huge role in achieving flame-polished

edges (FIGURE 5). It is important to have downdraft

suction beneath the acrylic to evacuate the gases so they

do not become “trapped” in the cut kerf. Without adequate

exhaust, a quality cut is not possible. Negative pressure is

more important than airflow.

FIGURE 5: Filters like this example from the Atmos line of exhaust

systems are necessary to ensure a clear, polished look to the edges.

The exhaust significantly reduces flaming. A good acrylic

cut is hot and produces gases, and gases are highly

flammable. The exhaust transports gases away and thus

avoids the possibility of igniting the gases. It also controls

frosting of liquid acrylic. The exhaust creates airflow

through cut kerf, letting the acrylic melt from top to

bottom, which creates a smooth, flame-polished cut instead

of wavy horizontal lines.

You should use compressed air or standard air assist and

a large diameter nozzle to transport gasses away through

the exhaust. The pressure should be maximum 1.5 PSI (0.1

bar).

Everything from signange, like the room number sign shown above, to intricate art can be cut

from acrylic.

Post Processing

That’s the beauty of laser. Unless you are

joining acrylic pieces together, there really is

no post processing. However, joining acrylic

pieces can be challenging because laser

processing applies heat to the material, and

the heat stresses the material. To avoid micro

cracks when you are joining, you should

temper your material for a few hours at 80° C.

Then follow the joining guidelines suggested by

your acrylic manufacturer.

Resources

I recommend taking advantage of forums

and associations—like the Awards and

Personalization Association and the

Member2Member Forum—where you can

share your experiences, get advice from

other engravers, and take advantage of the

networking opportunities. And don’t be

afraid to reach out to your material and laser

providers for applications assistance.

Good luck!