Get newest Ricoh sublimation printers from Marco Awards Group.

Apparel Decoration Processes

The Right Machines Make Every Job Easier

1. Get Newest Ricoh Sublimation Printers from Marco Awards Group

Marco Awards Group launches the new Ricoh family of printers. The Ricoh SG3110DN prints 81/2-in.-by 11-in. and 81/2-in.-by-14 in. sublimation transfers and the Ricoh SG7100DN prints up to 11-in.-by-17-in. sublimation transfers. The Ricoh printer series uses Sawgrass GelJet inks. Marco offers the individual printers and three Ricoh business packages that include the printer, a full set of Sawgrass inks, and TexPrint Paper. With 34 warehouses nationwide, Marco prides itself in getting your products to you the same day or next day.

Phone: 800.229.659

Website: www.marcoawardsgroup.com

2. New Mimaki Printers Are Compatible With Sublimation Inks

Mimaki USA recently introduced the JV150 Series printers and CJV150 Series cut-and-print devices. These models broaden the JV and CJV series families to bring proven platform capabilities to print service providers demanding high-quality, versatility, and reliability but in smaller volumes.

The JV150 Series is based on the JV300 Series platform introduced earlier this year and is available in two sizes: 54-in. JV150-130 and 64-in. JV150-160. JV150 Series models feature advanced piezo technology print heads capable of print speeds of up to 605 square feet per hour. These printers can use either SS21 eco-solvent inks or Sb53 dye-sublimation inks.

SS21 eco-solvent inks for the JV150 Series are available in eight colors including cyan, magenta, yellow, black, light cyan, light magenta, light black, and orange, packaged in 440-ml. cartridges. SS21 eco-solvent inks are fast-drying and can print on hundreds of media choices.

Sb53 dye-sublimation inks are available in magenta, blue, yellow, black, light magenta, and light blue and are packaged in 440-ml. cartridges.

Based on the recently-introduced CJV300 Series models, the CJV150 Series printers add cut-and-print capability for signage or textile applications. CJV150 Series models feature advanced piezo head technology and can print at speeds of up to 605 square feet per hour. These cut-and-print devices can use either SS21 eco-solvent inks or Sb53 dye-sublimation inks and are available in four sizes: 32-in. CJV150-75, 43-in. CJV150-107, 54-in. CJV150-130 and 64-in. CJV150-160. SS21 eco-solvent inks for the CJV150 Series are available in ten colors, including white and silver packaged in 220-ml. cartridges along with cyan, magenta, yellow, black, light cyan, light magenta, light black, and orange packaged in 440-ml. cartridges. Sb53 dye-sublimation inks are available in magenta, blue, yellow, black, light magenta and light blue, and they are packaged in 440-ml. cartridges. The integrated cut functionality enables short-run or custom production of labels, decals, T-shirt transfers, vehicle markings, package prototypes and more in a single unit.

SS21 Silver ink, available for the CJV150 Series, can be used to create metallic color effects, which are in high demand for label, decal, and package prototyping applications. This silver formulation delivers brilliant mirror-effect results that are not diminished even when film overlaminate is applied. RasterLink6 RIP software – standard with CJV150 Series units—includes a swatch palette of 648 metallic colors that are easily selectable from Illustrator® and can be used in a near endless combination of custom colors.

The CJV150 Series offers the same advanced cutting functions included in the CJV300 Series models, including continuous registration mark detection to enable cutting of an entire roll of media without interruption. Over-cut and corner-cut functions reduce waste by ensuring clearly cut edges with no uncut fragments. The segment correction function facilitates precision cutting over long-length prints, even if the image is distorted. Also included is a cut-and-print function for pre-cutting before printing, which prevents common problems such as film separation and other issues related to post-cutting on thin materials.

JV150 Series and CJV150 Series printers include RasterLink6 RIP software and a one-year warranty. Additionally, the CJV150 Series includes FineCut8 plug-in for Illustrator and CorelDRAW® and Simple Studio print-cut software.

Phone: 888.530.4021

E-mail: info@mimakiusa.com

Website: www.mimakiusa.com

3. JDS Proudly Supplies Heat Presses that Are Made in the United States

JDS Industries, Inc., proudly offers heat presses made in the United States from the leading companies in heat press manufacturing. GeoKnight is a 129-year-old manufacturing company that has been making quality heat presses for more than 40 years. Insta Graphic Systems has specialized in making quality heat transfer machines since 1959. Hix® Corporation has been manufacturing garment decorating equipment for more than 50 years. All of these companies’ products are American made and exhibit exemplary standards of quality. JDS is proud to supply these brands to the company’s customers. To place an order or for more information, contact JDS.

Phone: 800.843.8853

E-mail: sales@jdsindustries.com

Website: www.jdsindustries.com

4. Give Yourself an Extra Hand—or two!—at the Heat Press

Stahls’ Hotronix® recently released a heat press accessory to help decorators when they need an extra hand while using a Hotronix Heat Press Caddie™ or Air Fusion® heat press. The new Hotronix Heat Press Caddie™ Shelves allow the user to keep heat transfer products and blanks within reach during the application process. The innovative system came from customer and employee feedback on how to make heat printing on a caddie or pedestal base heat press more efficient when counter space is limited or out of reach.

The Caddie Shelves easily attach to the pedestal of the Hotronix Heat Press Caddie™ or Air Fusion®. Two trays make up the Caddie Shelves, which can be rotated in landscape or portrait positions, offering the heat press user convenience and flexibility. Made of aluminum, the Caddie Shelves are durable and can be folded underneath the heat press when not in use.

Phone: 800.727.8520

Website: www.hotronix.com

5. Vastex Drying Cabinet Dries Garments Faster

An all-new Dri-Cab Forced Air Screen Drying Cabinet from Vastex International dries coated screens five times faster than passively ventilated drying cabinets. The VDC-2331 Dri-Cab is the latest addition to its line of high-quality, affordable, space-saving equipment specially engineered for smaller shops and entry-level screen printers. With the VDC-2331 Dri-Cab, you can coat and expose your screens the same day, instead of waiting overnight for air drying.

The compact unit can hold up to 10 23-in.-by-31-in. screens, and features a positive-pressure ventilation system with air filter to prevent dust contamination—a common cause of pinholes in air-dried screens. The pressurized cabin dries most coated screens in less than 1 hour.

To ensure total darkness, the unit is constructed with large overlapping seams, and it is equipped with a latching, rubber-sealed door and light-tight bottom exhaust port. Screens sit horizontally on removable shelves that are angled to prevent screen mesh fabric from touching the shelf surface.

With its forced-air design, simple on/off switch, and easy-access filter housing, the VDC-2331 Dri-Cab is economical to operate and easy to clean and maintain. Equipped with locking casters, it can also serve as a mobile stand for a Vastex E-200 or E-1000 LED exposing unit, D-100 Conveyor Dryer, V1000 tabletop press or other tabletop equipment, which saves on floor space.

The company also manufactures screen printing presses, athletic numbering systems, screen registration systems, infrared conveyor dryers, flash cure units, screen exposing units, washout booths and complete screen printing shop systems, and offers a comprehensive range of training classes for entry level, intermediate, and advanced screen printers.

Phone: 800.482.7839

Website: www.vastex.com

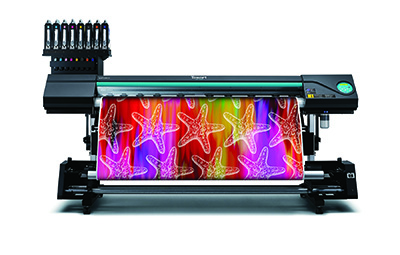

6. Roland Introduces Texart RT-640 Sublimation Printer

Roland has introduced the Texart RT-640, an advanced, 64-in. dye-sublimation transfer printer featuring innovative print control technology, powerful ErgoSoft Roland Edition RIP software, and a choice of four- or eight-color ink configurations. The Texart RT-640 incorporates a host of technological advancements that optimize sublimation transfer output while minimizing running costs. The RT-640’s variable droplet technology in combination with Roland Texart dye sublimation ink displays bold, vibrant colors and rich, velvety blacks, as well as subtle gradations and fine details.

The Texart RT-640 incorporates a gold-plated, anti-static print head capable of printing seven different droplet sizes for smooth gradations and denser color. A newly designed feed adjuster which, in combination with a more powerful fan and an included TU-3 take-up system, ensures added stability for high-speed printing up to 351 sq ft per hour.

Roland’s RT-640 is equipped with a bulk ink system that uses airtight-sealed pouches of 1 liter each. The Roland Ink Switching System™ allows users to load a fresh pouch without stopping the printer. In four-color CMYK mode, the system provides 2 liters per color and automatically switches to a backup ink pouch when the primary pouch runs out.

ErgoSoft Roland Edition RIP is a powerful tool for either four (CMYK) or eight-color (CMYKLcLmOrVi) ink configurations. Adding orange and violet inks increases color gamut and allows for exceptional reds, oranges, deep blues and purples, while light cyan and light magenta provide subtle gradations and beautiful skin tones.

Phone: 800.542.2307

Website: www.rolanddga.com

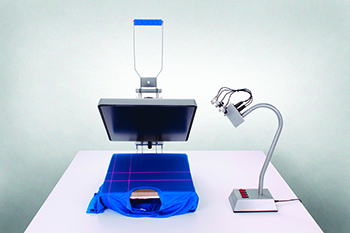

7. Portable Heat Press Laser Alignment System Debuted by Stahls’ Hotronix

Stahls’ Hotronix® has introduced the industry’s first Portable Heat Press Laser Alignment System that can be used with any heat press brand. It allows the user to precisely position and align graphics prior to heat printing for accurate placement.

Four flexible laser lights can be adjusted independently to set placement for left chest, name and number, script, and other design layouts. Each light is operated individually with the touch of a button. The unit has a solid steel base with rubber feet for counter or tabletop placement and requires 18 in. of space. It is compatible with all Hotronix and MAXX® heat presses and competitors’ models.

The Laser Alignment Wizard™, which comes with the system, is preprinted with five popular layouts and rulers for custom layouts. This handy tool is used for initial set up for each heat printing job. A 6-ft electrical cord with A/C adaptor is included. For more information, visit www.stahls.com/portable-laser.

Hotronix®, a GroupeSTAHL company, designs, engineers, and manufactures innovative and technologically advanced heat press machines. Made in the United States and engineered by experts, Hotronix® heat presses are product safety certified.

Phone: 800.727.8520

Website: www.hotronix.com