Engraving, etching, and cutting with a CO2 laser system is simple and fast. These versatile machines excel at engraving wood, glass, acrylic, specialty plastics, and many textiles.

Make Your Mark on Metal!

Expand Substrate Options for Your CO2 Laser with CerMark™

BY MARK CONDE, FIREPOINT CREATIONS, FISHERS, INDIANA

Engraving, etching, and cutting with a CO2 laser system is simple and fast. These versatile machines excel at engraving wood, glass, acrylic, specialty plastics, and many textiles.

Lasers can even mark a marshmallow and many other foods. Plus, it can cut many pieces of the same material in one pass.

The laser is the Superman of the engraving and cutting world—but its kryptonite is metal. The CO2 laser mostly bounces off many metals, barely leaving a mark. (Other laser types are able to mark bare metals, but many retailers only have a CO2 laser.) With a little help from CerMark™, the process of marking metal can be as fast as a speeding bullet.

Ferro Corporation’s CerMark is a patent-protected product that the user coats on top of the metal. It’s available in several versions. After about 5 minutes of drying time, the substrate can be lasered like a normal laserable material. When the CerMark is hit with the laser beam, a thermochemical reaction occurs, creating a bond that results in a black mark on the metal. The metal is not engraved (which would remove layers of the substrate) but permanently marked (which adds a layer of bonded CerMark about .004 in. high).

USING CERMARK

CerMark is available in three basic versions:

Heavy Paste

This version must be diluted with a solvent such as denatured alcohol before being brushed or sprayed onto the substrate. Some users load the diluted mixture into an airbrush system while others like to brush it on with a foam brush. Whatever your preferred method of application, be sure you don’t apply it too thickly because it will require more laser energy to achieve a bond with the metal. The paste version is excellent for small objects. When brushed on the substrate, very little is wasted. This version is my favorite.

Aerosol Spray

The CerMark is premixed and dispensed through a spray-can. The aerosol spray allows you to quickly lay down an even coat. Overspray is inevitable, however, resulting in wasted product. Still, the aerosol can is the most convenient and consistent method for applying CerMark.

Tape

CerMark tape is available in 1-in., 2-in., and 4-in. widths. There is no mixing and no overspray. Simply stick the tape on the metal and engrave as usual. You’ll need a laser that is at least 45 watts to generate enough power to leave an acceptable mark. I dislike the tape because it does not provide a strong, black mark consistently for me.

METALS THAT WORK WELL

Not all metals can be marked successfully with CerMark.

- Metals that work well: Stainless steel, steel, aluminum, cast iron, and pewter.

- Metals that require a laser of at least 45 watts: Brass, copper, nickel, silver, and titanium.

- Metals that should not be used with CerMark: Gold

Even if a metal can be marked using CerMark, be aware that metals simply look better when rotary engraved through the diamond drag process. Gold, silver, and even brass may be more attractive when rotary engraved instead of using CerMark. It’s like going to a dinner dance in cut-off jeans and T-shirt. Sure, you can do it, but you’re going to look out of place.

STEP-BY-STEP CERMARK USE

1. Clean the metal with denatured alcohol as shown in FIGURE 1. Ensure all dirt, oil, and lint is removed. Make sure the metal is not coated with a lacquer coating. Soaking the metal in lacquer thinner will usually remove any top coating on the metal. If the material is not properly cleaned, the CerMark will not bond with the metal. The CerMark must be directly on raw metal.

FIGURE 1: Denatured alcohol removes oil and dirt to help the CerMark bonding process.

2. Brush or spray a thin coat of CerMark on the metal. The coverage should be no more than 1 mil thick as shown in FIGURE 2. Thicker coatings will require more laser energy and may result in a weaker mark.

FIGURE 2: A 1-mil-thick coat of CerMark works best.

3. Let the CerMark dry completely. This should only take about 5 minutes. You can use a heat gun or hair dryer to speed up the drying process. When dried, the CerMark should be hard and not flake off the metal. Sometimes, CerMark will not adhere well to chrome or highly polished steel. If that’s the case on a piece you’re working on, talk to your distributor about special CerMark products that are available for chrome and other highly polished metals.

4. Place the substrate with the dried CerMark on your laser bed. Laser with the appropriate settings. In general, CerMark requires high power and low speed. This chart suggests settings for CO2 laser systems, but your settings will depend on your laser’s make and model. Experiment with these settings; you may need to slow the speed to achieve an acceptable mark.

SUGGESTED LASER SETTINGS FOR CERMARK

|

SPEED |

POWER |

| 30-Watt Laser |

10 |

100 |

| 40-Watt Laser |

15 |

100 |

| 50-Watt Laser |

20 |

90 |

| 60-Watt Laser |

25 |

80 |

| 80-Watt Laser |

35 |

80 |

5. When the laser is complete, remove your substrate (FIGURE 3) and wash off the remaining CerMark with warm, soapy water (FIGURE 4).

FIGURE 3: The CerMark has bonded to the metal, but excess CerMark remains.

FIGURE 4: Use warm water and soap to removes the excess CerMark.

POOR MARKS?

When everything is done correctly, CerMark creates a dark mark that doesn’t wash away. If your marks do wash away, the cause is typically one of the following issues:

- Oil, dirt, or lacquer was on the metal, making it impossible for the CerMark to bond with the metal.

- Not enough power was used to make a bond.

- The CerMark was too old to still be potent.

If you get a light or faded result, you can reapply the CerMark and repeat the process, but your metal piece must be aligned perfectly to get a good mark.

THE TEST OF TIME

Traditional engraving is well accepted throughout the world. The earliest engraving we have is a shell with a zig-zag pattern that was created 430,000 and 540,000 years ago by Homo erectus in present-day Indonesia. CerMark, on the other hand, has only been around for the past 20 years, dating back to the mid-1990s.

Though CerMark is relatively new, it has some heavy-duty and reputable experience. When used on steel or stainless steel the mark is exceptionally durable. To fully remove the mark, you’d have to sand down to the bare metal.

In testing performed by the manufacturer and users around the world, CerMark has survived the heat of a blowtorch and arctic temperatures. It even has held up well to solvents like mineral spirits, lacquer thinner, and naphtha.

CerMark has even found its way into the International Space Station, surviving 4 years in space with no degradation.

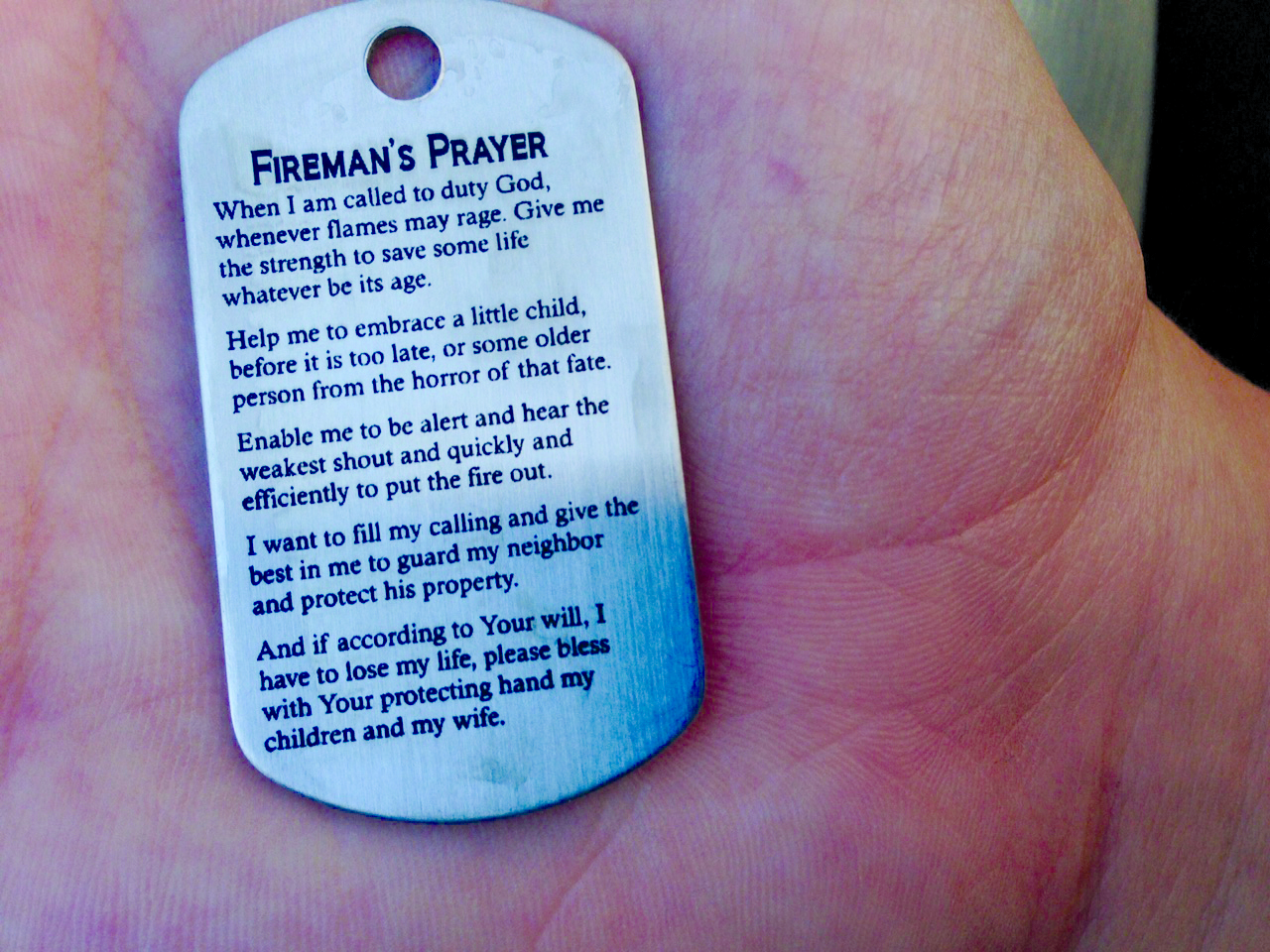

One of the best features is the fine resolution possible when using CerMark and laser systems. We often mark dog tags with fonts as small as 6 points, but as you can see in FIGURE 5, the mark is crisp and clean.

FIGURE 5: The CerMark creates a dark, fully bonded mark on the metal that does not wash off.

CerMark also is available in other colors to create marks that look copper, red, yellow, or blue. Though our industry frequently uses it on metal, it also works with glass and tile.

Mark Conde has been in the awards and personalization industry since 2011. He and his wife, Lisa, own and manage FirePoint Creations with their sons. FirePoint Creations offers personalized gifts and awards online because Conde’s passion for laser systems is as deep as his passion for e-commerce. If you have questions or comments for Conde, e-mail Mark Conde.