Interest in DTF—or direct-to-film—printing is growing every day.

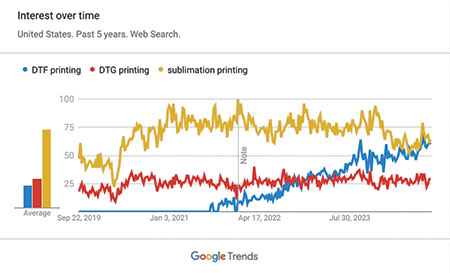

A quick search on Google Trends reveals that, over the past five years, Americans are searching more for DTF printing year over year.

DTF printing has lots of unique benefits. It can save you time and cost while also creating pixel-perfect transfers for almost any garment in any color.

How To Decide If DTF Printing Is The Right Move For Your Business

Weighing the Pros and Cons of the DTF-Printing Method

By John Modi, Chief Imagination Officer at MakerFlo Crafts

(Originally printed in the November/December 2024 issue of Insights.)

Interest in DTF—or direct-to-film—printing is growing every day.

A quick search on Google Trends reveals that, over the past five years, Americans are searching more for DTF printing year over year.

DTF printing has lots of unique benefits. It can save you time and cost while also creating pixel-perfect transfers for almost any garment in any color.

In this article, we’ll explain the basics of DTF printing, how to do it in-house, and what to consider before buying a DTF printer for yourself.

What Is DTF Printing?

DTF is a method in which you print an image onto film with a DTF printer, add a powder-based adhesive, then adhere the image to a garment with heat.

You can apply a DTF transfer to nearly any type of fabric. As long as your substrate can be pressed with a heat press, it should work just fine.

However, DTF transfers don’t adhere to hard substrates like metal or plastic. For things like tumblers, you’ll want to look into UV DTF printing—but that’s a topic for another article.

Why Choose DTF Printing?

DTG printers use digital files, which makes it easy to print crisp full-color graphics like photos or illustrations. It’s a cinch to print small batches or create custom designs for each order.

Since you’re printing on sheets of film, you can print multiple images on one sheet to save time and money (these are called gang sheets). Plus, you can save your DTF transfers for later use or even sell them as products.

With DTF printing, you can print with white ink. That means your transfers show up beautifully on any color of fabric. The printers also produce the full CMYK (cyan, magenta, yellow, and black) gamut.

America's interest in DTF printing from September 22, 2019, to July 30,2023.

What are the downsides? Yes, there are a few. The main downside is that the process has multiple steps, including adding the adhesive and curing it. If you’re doing this by hand, it can take time and effort.

Another downside is the adhesive powder is toxic and irritating to the skin and lungs. But if you use protective gear or invest in an automatic powder shaker, you can sidestep this issue.

Lastly, DTF printers are relatively new to the market and can take some trial and error to set up. And once you have them set up correctly, they need daily maintenance to stay in good condition. However, if you’re a commercial print shop, this shouldn’t be too big of an issue.

How to Make a DTF Print

Now how does this all work? Let’s walk through the printing process step-by-step.

A word of caution: As stated above, DTF powder is toxic, so please exercise caution and wear protective gear when working with DTF printers.

Step 1: Print the Design

Use a DTF printer to print your design onto a piece of DTF film.

Of course, you’ll need to print a mirrored design because you’ll transfer it later, but the included printing software should help you get the settings just right.

Step 2: Apply Adhesive Powder

Before the ink dries, apply DTF powder to the print, either by hand or with an automatic shaker. This is a powdered adhesive that cures with heat.

You or the machine will shake the powder generously over the print and then shake off any excess.

Step 3: Cure Adhesive and Create a Transfer

Apply heat to the adhesive powder with a heat gun, heat press, oven, or automatic curing machine. If using a heat press, hover the press over the design until the adhesive cures.

The powder will melt and dry over the ink to create a DTF transfer. Once it’s cool, you can store it away for future use or press it right away.

Step 4: Press the Design

Tape the transfer with the adhesive side facing down onto the garment or fabric you are customizing. Press it with a heat press for the recommended time and temperature (see your DTF-film instructions for details).

Peel off the transfer, and it’s done. You’ll have a beautiful, vivid, and durable print that really pops!

Should You Invest in a DTF Printer?

As you can see, DTF printing can be an excellent business opportunity, but what about your bottom line? Let’s explore the investment costs and what you would need to hit the ground running.

Here’s what you’ll need to buy:

- A DTF printer

- DTF ink

- DTF powder adhesive

- DTF film

- An optional automatic powder shaker and/or curing machine

- A heat press

DTF printers range in price depending on the features you’re looking for. Some options will do all the printing, shaking, curing, and cutting for you, but they will come at a steeper price.

Here’s what you want to consider when choosing a DTF printer:

- Safety: How will you ensure a safe environment for your workshop and employees with the use of these materials? Will you invest in an automated setup or do the adhesive part by hand?

- Size of Prints: What’s your desired print size? Bigger print sizes mean you can print larger gang sheets to save time.

- Size of Machine: Where do you plan to store the printer?

- Cost of Ink and Supplies: How much will the ink and film cost to replace?

- Track Record of Company: Does your printer manufacturer have a good track record of maintenance and support? Are you confident you can reach them and get help when you need it?

An Affordable Way to Try DTF Printing

You don’t have to buy a DTF printer to start offering custom DTF prints for your clients.

If you’re not quite ready to drop a large amount of money for a printer—especially if you haven’t tested out DTF printing as a product offering—there’s another way you can try out the method at a fraction of the cost.

Instead, send your designs to a DTF-transfer provider, have them make gang sheets for you, and transfer them in-house to create your own DTF-printed products. You still get full design control, but you don’t have to buy and maintain a printer.

This way, you can test out designs and see if DTF printing has the potential to be profitable for you. If it is profitable, you can confidently invest in a DTF-printing setup, knowing that it’ll create a good return on investment for your business.

No matter what you decide, it’s worth considering this fast-growing print method and its potential to grow your bottom line. If trends continue as they are, we’ll be seeing a lot more of DTF printing in the years ahead.

John Modi is the creative mastermind behind MakerFlo Crafts, a business dedicated to teaching and empowering others to elevate their crafting or hobby. With his quirky sense of humor and a sharp focus on quality and presentation, he inspires both hobbyists and

entrepreneurs to grow their ventures in innovative and meaningful ways. When he's not collaborating with his business partner, Marc Pendergraft, Modi enjoys working with makers to spread the joy of crafting far and wide. Learn more at makerflocrafts.com.