No guts, no glory.

For sole proprietor Michael Mullins, relocating Sonoma Laser Engraving from California to Georgia in 2019 was a bold move. His personalization business relied heavily on a local customer base, and he knew he would essentially have to start from scratch. But, with extended family closer in Georgia and the promise of new work opportunities, he and his family packed their things and moved across the country.

Sonoma Laser Engraving: A Case Study in Customer-Centric Service

Michael Mullins’ creative vision and efficient practices drive the success of Sonoma Laser Engraving.

By: Stefanie Galeano-Zalutko

(Originally printed in the May/June 2024 issue of Insights.)

No guts, no glory.

For sole proprietor Michael Mullins, relocating Sonoma Laser Engraving from California to Georgia in 2019 was a bold move. His personalization business relied heavily on a local customer base, and he knew he would essentially have to start from scratch. But, with extended family closer in Georgia and the promise of new work opportunities, he and his family packed their things and moved across the country.

In historic Roswell, merely a stone’s throw away from downtown Atlanta, Mullins converted his family basement into a 1,000-square-foot professional workshop, quite a bit smaller than his 3,000-square-foot warehouse back west.

However, even with the changes and the challenges, the move proved to be both personally fulfilling and profitable. New beginnings not only brought the Mullins family closer together but also provided the ideal backdrop for his business to flourish.

“Sometimes, less turns out to be more,” he says.

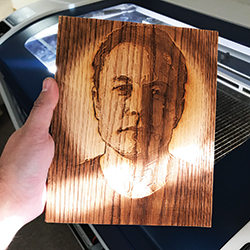

Today, Sonoma Laser Engraving is thriving in that basement. The one-man show is a one-stop shop for specialty laser engraving and personalization services. From fine jewelry, glassware, and leather products to tools, medical equipment, and firearms, there’s little Mullins cannot meticulously laser cut and engrave. And his quality craftsmanship is attracting diverse customers, with clients ranging from large corporations to everyday consumers on big-budget projects and family heirlooms alike.

Armed with commendable business acumen and an inner grit, Mullins can serve as a case study for other industry professionals to model.

Differentiation in a Growing Market

The personalized-gift market is expected to increase from $51.98 billion in 2024 to $138.17 billion by 2030, according to Market Research Future. An appetite for customization is influencing consumer demand in categories like personalized apparel, home decor, accessories, and drinkware.

As laser engraving continues to evolve, Mullins says two distinct business models are paving the way in the industry: product centric and customer centric.

In a product-centric business model, it’s common for shops to partner with suppliers to purchase a variety of blank items, then engrave and resell the finished product, according to Mullins. The entire operation is geared toward mass production, rather than niche customization.

By contrast, a customer-centric business model, like Sonoma Laser Engraving’s, is focused on transforming personal possessions into cherished keepsakes, such as a wristwatch, knife, or firearm specially engraved for a loved one; a charcuterie board donning the family moniker; or tumblers and glassware commemorating a bachelorette party, bridal shower, or wedding.

To be successful with a customer-centric business model, Mullins says the staff must be proficient in a variety of materials, finishes, and sizes.

“The primary advantage lies in the ability to cater to individual preferences, making each engraved item both unique and meaningful,” he says. “People will travel for quality engraving.”

Mullins points to expertise in cutting-edge equipment as another differentiating factor in the business’s success. With CO2 and fiber-laser machines on-site, Sonoma Laser Engraving can confidently accept any job that comes through the door.

Mullins points to expertise in cutting-edge equipment as another differentiating factor in the business’s success. With CO2 and fiber-laser machines on-site, Sonoma Laser Engraving can confidently accept any job that comes through the door.

“Part of my success is that I don’t have to say no,” Mullins says.

Keeping It Creative

Sonoma Laser Engraving navigates between two distinct streams of project inquiries: those originating from business entities and those from individual customers.

Many corporate projects are uniform requests—500 Stanley cups or 100 knives drop-shipped to the shop for specialty engraving then shipped back to the customer upon completion.

“You tend to know exactly what you’re getting into with these projects, so it’s rather easy to set up and just repeat the process,” Mullins says.

Other projects originating from business entities are when Sonoma Laser Engraving is a middleman in the manufacturing or branding process—like engraving equipment or promotional items.

While these projects are valuable low-hanging fruit, Mullins relishes the creative satisfaction of personalized gift packages or one-off projects that celebrate individuality.

He recalls an unorthodox request involving a large wooden airplane spanning at least eight feet. The project required an expert blend of skill and ingenuity to fit the desired plane part in the machinery to engrave a logo. Later, the finished product was displayed at a nearby museum.

He recalls an unorthodox request involving a large wooden airplane spanning at least eight feet. The project required an expert blend of skill and ingenuity to fit the desired plane part in the machinery to engrave a logo. Later, the finished product was displayed at a nearby museum.

“You just never know what people are going to bring you,” he says. “A customer could call and say he or she is bringing in some glasses, only to show up with diamond-and-gold-encrusted glassware that makes the job much more complex—and custom.”

Mullins tends to steer clear of orders related to trophy name plates and plaques—preferring to refer those customers to a local trophy and awards shop. If a company wants Mullins to design, engrave, or build 100 custom awards from scratch, however, that’s right up his alley.

“[In the end] no matter the customer, B2B or B2C, I get to make what they have in their head a reality—and strive to exceed those expectations by 100 percent.”

Mullins stresses the importance of not only having the right laser-engraving equipment on-site to bring mental sketches to life, but also investing in one’s expertise with the hardware and software.

“With laser engraving, you must understand the graphic design part of the business,” he says. “If you aren’t highly proficient in CorelDRAW or Illustrator, then that’s just as big of a learning curve to overcome as the machines themselves.”

Crafting graphics, having an eye for layout, working with customer files, and properly lining up the projects are all part of the workflow—and integral to a successful finished product, says Mullins.

Client Diversification

While Sonoma Laser Engraving caters to personalized gifts for a myriad of special occasions, the specialty shop is also a partner to businesses in the engineering, industrial design, and manufacturing sectors. Mullins points to medical-device contracts as an example. Sometimes he performs microscopic engravings on medical devices that need to be verified with a digital microscope. These devices are made from a specific titanium material that engraves differently than steel or aluminum.

“There’s no room for error when these implants are going into the human body. If I get a batch of 800, they all need to be precise and consistent,” he says.

Such work requires top-tier skill and a lot of backbone, but he says it is highly profitable for qualified professionals.

Movie props are another unexpected area of growth for Sonoma Laser Engraving. Mullins calls Atlanta the new Hollywood, highlighting its picturesque landscapes and affordable filming opportunities. As such, Netflix and Paramount are repeat customers for him, with prop masters requesting one-off specialty items on quick turnarounds. Sometimes movie-set personnel know exactly what they want. Other times, Mullins gets to make suggestions.

Last year, he made a custom bracelet featured on the Netflix hit Pain Hustlers. On other occasions, he was asked to create personalized gifts for staff upon completion of a film.

“Getting into the film industry definitely was not a revenue source that I originally considered, but the projects are cool, fun, and profitable,” he says.

Looking Ahead

Like any successful small business owner, Mullins is knee-deep in the day-to-day grind, methodically planning his day to account for both administrative and operational tasks. From organizing new customer requests to finalizing revisions and checking the job board to determine the day’s priorities at each machine, Mullins is present and engaged in the process.

While the immense circle of work is a proud rite of passage for sole proprietors, the business owner is excited to expand operations—and head count.

According to Mullins, there is a fine art to expansion.

“Do what you’re doing until you’re ready to bust at the seams—then it’s time,” he says. “And I’m just about there.”

Until recently, Mullins shouldered the weight with part-time help in mock-ups, proofs, engraving, and social media. His assistant, Dana, has been a “jack of all trades,” he says, operating the laser-engraving equipment, as well as filming and editing for the company’s YouTube channel @sonomalaserengraving5864.

Mullins says part-time workers like Dana, who “take good direction and initiative,” will be essential during the next stage of growth.

The website is also being revamped. It will include an improved online store to house a multitude of unique products that are ripe for personalization, from rustic live-edge cutting boards to trendy leather-patch hats and memorable decanter sets.

Operations are expanding, but Mullins assures quality will not suffer. Rather, the online store will grant more customers easier access to the handcrafted finished products synonymous with Sonoma Laser Engraving. Mullins is preparing to launch the store by Q4.

Mullins is also searching for a new workspace near a main road to encourage increased foot traffic. A larger location will accommodate the equipment, an expanded workshop, and proper retail area.

As the business expands in size and scope, Mullins is eyeing new equipment as well.

“I’m starting to see UV printing make a resurgence. It keeps popping up, and there’s a reason for that,” he says. “If the innovation and reliability are where they need to be, then I’d like to incorporate UV printing into future business because it pairs nicely with laser engraving.”

Having a Presence

Regardless of what lies ahead, Mullins says an online presence will be instrumental in the company’s long-term success. He points to social media as a valuable tool in building and promoting Sonoma Laser Engraving’s personal brand. Active on Facebook, Instagram, and YouTube, Mullins discovered a sweet spot in curating unique content for each platform.

The result? He not only showcases the art of laser engraving, along with an impressive gallery of work, but also positions himself as a thought leader in the field.

For Mullins, YouTube scratched an itch during COVID.

For Mullins, YouTube scratched an itch during COVID.

“I had to figure out what to do when the phones stopped ringing, and no one wanted to be near anyone,” he says. “I’ve been proficient in laser engraving for over 10 years. I thought, ‘I can share this [craft] with others through video.’ So, I pivoted and [embraced] being an educator. When people were ready to come out of the woodwork, they came to me.”

As Mullins prepares to do a hard push with the online store, he expects social media to play an even bigger role in product promotion.

“The juice is worth the squeeze with social media,” he says, encouraging fellow industry professionals to invest in quality content. “The more I learn, the more effective I am.”

Mullins points to APA membership as another perk in business building. He touts the educational component as vital to the future of the industry at large. From new ideas, trends, and processes to networking, attending trade shows, and taking courses, APA bridges connections and fosters meaningful industry relationships.

There is nowhere to look but up, he says.

“To my fellow laser-engraving professionals: Know your worth, and don’t undersell yourself.”

Stefanie Galeano-Zalutko leads Zalutko Business Services, Inc., a marketing agency based in Central Florida. She can be reached at szalutko@zalutkobusiness.com.