When it comes to personalized products in the sports and academic field, and beyond, tumblers stand out as not only a popular choice for keeping beverages at the desired temperature but also as an excellent canvas for personalization. Vacuum-insulated tumblers have been on the market for a decade or more. Many thought they would be a passing fad, but this type of beverageware has proven its staying power.

Laser Hack: How to Engrave Multiple Tumblers at Once on a Rotary

By: David Stevens, Technical Development Manager, Trotec Laser

(Originally printed in the March/April 2024 issue of Insights.)

When it comes to personalized products in the sports and academic field, and beyond, tumblers stand out as not only a popular choice for keeping beverages at the desired temperature but also as an excellent canvas for personalization. Vacuum-insulated tumblers have been on the market for a decade or more. Many thought they would be a passing fad, but this type of beverageware has proven its staying power.

The tumbler’s popularity has turned it into a lucrative product for businesses in the personalization industry. Tumblers can attract a steady stream of customers looking to add that personal touch to their drinkware, hand out functional awards to their sports teams, or gift a little school spirit to their teaching staff.

However, lasering one tumbler at a time on a rotary can be extremely inefficient. To capitalize on the popularity of tumblers, it is important to find ways to cut down production time. This hack will show you how to process tumblers three or more at a time in your laser. Just follow these steps:

Purchase non-slip silicone coasters: Off-the-shelf coasters can be purchased easily at Amazon.com. Just scan the QR code at right for non-slip coasters that fit on 20- and 30-ounce tumblers. Other similar rubber sleeves will also work for this as long as they can fit snugly on the bottom of a tumbler. Make sure to buy enough (at least six) so you can get a second group of tumblers ready to be quickly exchanged once the first group is finished.

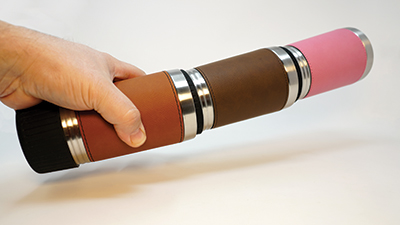

Prepare the tumblers: Place a silicone rubber coaster–or a similar rubber sleeve–on the base of each tumbler that will be laser processed. These act as a non-slip grip that stabilizes the tumblers during the engraving process and ensures precision.

Stack the tumblers: Stack the tumblers on top of each other. Ensure they are secure and stable. This stacking method uses the coasters to create a non-slip gasket-like effect. You can stack as many tumblers as you can fit in your rotary.

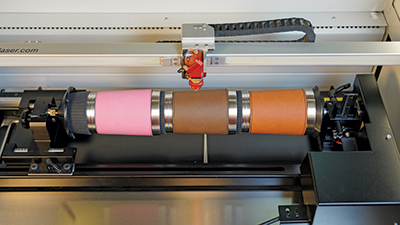

Load the tumblers: Carefully load the stacked tumblers into the rotary attachment of your laser engraver.

Focus the laser: Adjust the laser to focus on the average location of the engraving area across the stacked tumblers. This ensures the laser engraves each tumbler with optimal clarity and precision.

Design your graphics: Measure the distance between each stacked tumbler and design a graphic to match that is appropriately scaled and positioned. You can choose to have the same design on all tumblers or different designs on each.

Send the file to the laser: Once the graphics are ready, send the file to the laser engraver, turning on the rotary. Then enter the diameter of the tumblers (the same as running one at a time).

Start the engraving process: Once the file is placed, press start and run the design files onto the tumblers. The laser will have a much longer stroke, producing close to triple the productivity and only requiring one-third the amount of laser off time as you load and reload more tumblers.

Prepare additional sets: While the laser is running, you can prepare additional sets of tumblers by repeating the steps above. This preparation significantly reduces downtime, allowing for a continuous workflow.

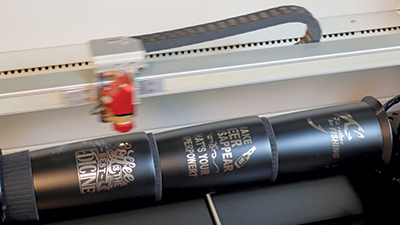

Once you’re finished, the results will be no different than if you ran one at a time, at least for most graphics. Given that this process will not allow for angle compensation, some highly detailed graphics, like images, may not work well with this process. However, most graphics produce clean finished results.

By adopting this method, you can increase productivity, reduce operational costs, and maintain the quality of engraving on most graphics. This hack proves invaluable for any personalization business looking to maximize efficiency and profit in the competitive and popular market of personalized tumblers.

For more laser hacks, go to youtube.com/@TrotecLaser