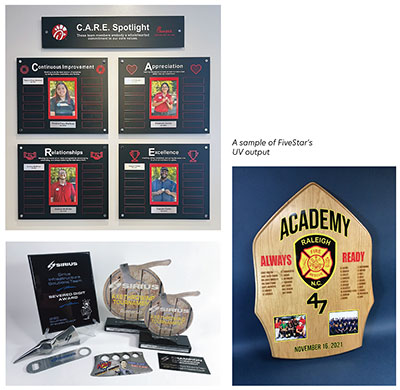

With UV printing, the sky’s the limit, says Lisa Higginbotham, CRM, president and owner of FiveStar Awards & Engraving in Cary, North Carolina. Higginbotham is a past APA president and has been in business since 1999, focusing on corporate awards. “UV printing gives you all kinds of out-of-the-box solutions for customers.”

A New Dimension

Retailers continue to tap into the vast potential of UV printing, greatly expanding capabilities.

By: Jason Henninger

(Originally printed in the January/February 2024 issue of Insights.)

With UV printing, the sky’s the limit, says Lisa Higginbotham, CRM, president and owner of FiveStar Awards & Engraving in Cary, North Carolina. Higginbotham is a past APA president and has been in business since 1999, focusing on corporate awards. “UV printing gives you all kinds of out-of-the-box solutions for customers.”

For the unfamiliar: UV printing uses ultraviolet light to dry or cure ink as it’s printed onto a surface. Part of the recent uptick in popularity is its durability, versatility and ability to produce vibrant colors. The ink is water- and scratch-resistant, and its quick-curing nature results in

a crisp and defined print, making it ideal for intricate designs and small text.

“I can take acrylic, cut it on my lasers and UV-print all kinds of creative designs, and I can do all of that in-house, so it has given me a lot of capabilities to be more visionary with my customers,” Higginbotham says. “It also creates buy-in with my customers because now they know they’ve got a company that is going to think about them, figure out their needs and create products specifically for those needs.”

UV ink uses compounds called “photoinitiators,” which react rapidly to light, unlike sublimation printers that require heat. One complication with UV ink is that the UV required to cure it needs to be matched to the surface tension of the substrate to avoid being brittle or having the ink fail to adhere correctly. However, this issue has little bearing on the vividness of the printing itself.

A sample of FiveStar's UV output

Higginbotham says she has a lot of cool toys in her shop, but “UV printers are my favorites.” (She currently has a Mimaki 6042MkII, a Mimaki 7151 PlusII and a Mimaki UCJV300-160.) Overall, she says that embracing UV printing has quite literally given her a new dimension to work with. “Where once all we could do was engrave words on a plaque—very one dimensional—now you’re looking three dimensional.”

Peak Flexibility

Versatility is perhaps the biggest draw with UV printers, as UV printers can work with a broader range of substrates and curved surfaces than sublimation. While acrylic is a popular choice, UV printers also work well with wood, leather, glass, canvas and metal.

“I can print on anything three-dimensional,” says Desiree Colonna, CEO and owner of Inkwell Designers in Woodstock, Georgia. Colonna has been UV printing for four of her seven years in business and specializes in creating custom work, including jewelry and holiday ornaments.

To use UV printing to create custom jewelry, Colonna makes a design, traces the outline and puts the outline into a cut file. She then cuts the design with a laser, often on 1/8-inch-thick acrylic, then prints. “My printer has the capability to print two sides at once,” Colonna says. “You’re seeing the design through the front and back of the earring. The only time that doesn’t work is when there are words because they will be backward on the back,” she says.

Creative applications on acrylic can include layering for multidimensional effects. Higginbotham says she’s selling a lot more acrylic for multi-level awards than in the days before getting into UV printing. She gave an example of a recent award for a barbecue competition, where a large flame was printed on one layer of acrylic with additional acrylic flame layers to the sides and the award text in the center. Colonna, meanwhile, recently used multiple printed layers for a placard featuring WWII fighter planes, where bullet holes were added via layers, giving the art a 3D appearance.

Creative applications on acrylic can include layering for multidimensional effects. Higginbotham says she’s selling a lot more acrylic for multi-level awards than in the days before getting into UV printing. She gave an example of a recent award for a barbecue competition, where a large flame was printed on one layer of acrylic with additional acrylic flame layers to the sides and the award text in the center. Colonna, meanwhile, recently used multiple printed layers for a placard featuring WWII fighter planes, where bullet holes were added via layers, giving the art a 3D appearance.

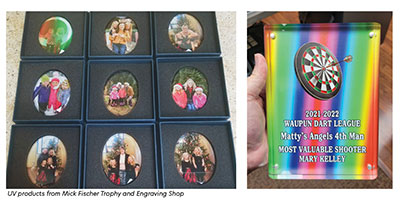

Justin Fischer runs the Mick Fischer Trophy and Engraving Shop in Beaver Dam, Wisconsin, which his father, Mick, opened in 1989. Fischer uses a LogoJET UVx40R PLUS, giving it high marks for “ease of use, efficient maintenance and high print quality,” which he says has been pivotal in the shop’s success. “The printer’s flexibility allows us to multitask and has revolutionized our production process,” he says. He’s used it for everything from yard signs with creative designs to tumblers and plaques, the latter of which has seen a surge in popularity due to high-resolution color printing, he says.

Fischer says his UV printer’s scalability and rapid turnaround times have significantly benefited his business. “UV printing has provided a competitive edge and opened up new market segments,” he says. “The printer has been instrumental in our company’s transformation and growth.”

Fully Covered

There are two UV printing methods for working with curved surfaces. One option revolves around using the printer’s own capabilities, where users calculate surface changes to modify the pressure at which the ink is ejected to match the curves. The other method involves UV direct-to-film (DTF) print, which uses UV ink on DTF sheets that can then be transferred, like a sticker, onto irregularly shaped materials. One advantage of this method is that you can print more than one object at a time. DTF can also be dishwasher safe.

UV products from Mick Fischer Trophy and Engraving Shop

“UV DTF is truly the future,” says Colonna, who has been using this method for about a year and a half. “If you’ve already been using a UV printer, it’s very easy to print on film and then peel it off. There are a lot of tips out there on how to do it, but it’s not hard. In fact, in a lot of ways, it’s easier than direct printing.”

Higginbotham agrees that the transfers are useful but also likes her printer for some curved surfaces. “We do have the transfer process. We’ve added that recently, mainly to do curved objects, although we can print on curved objects because the Mimaki 7151 PlusII has a really good long-distance profile. So, whereas before, every time we were doing cups, for example, you would run those on the rotary device. Now you can run them flat, which allows you to print several at a time.”

Color Concerns

With color output, UV ink is exceptionally vivid and clean due to its ability to be cured quickly, minimizing the chance of inks bleeding into each other. As with any equipment, color matching remains a concern.

“Color matching is a challenge,” Higginbotham says. “Not every company that does UV printing understands color matching. I’m fortunate because my background is in commercial printing, and matching colors was my area of expertise.”

UV products from Mick Fischer Trophy and Engraving Shop

Higginbotham suggests not relying too much on the machine itself. “It’s not a matter of just pressing a button and telling it, ‘OK, Pantone 485, go.’ Because you have to then hold your Pantone book over it and make sure that it really does match.”

She says that anyone can learn color matching with proper training, but no matter how good the technology gets, there will always be a skilled and manual aspect to it.

Fischer also says that color matching remains challenging, particularly with complex shades. “We often create samples for approval to ensure accuracy. The transition between RGB and CMYK can also be challenging. Having the brightest white surface to print color helps with color accuracy. UV printing allows you to print white as a base on almost anything.”

The Sales Piece

UV printers are hardly cheap, though, and Colonna feels the price may be prohibitive for some. “Honestly, they’re very expensive,” she says. “I hope in the future that they’ll come down in price because it’s just not open to everybody.”

Fortunately, the investment has the potential to become profitable quickly.

“Color sells itself,” Fischer says. “Providing samples has been an effective strategy, as customers often prefer the vibrant full-color options. This has led to a substantial increase in business without the need for aggressive advertising. UV printing has made us more competitive and versatile. We can now accept projects with complex graphics and color requirements, which were previously unattainable with other printing methods. My corporate business has picked up a lot because most companies like to see their Pantone matching system colors.”

Clear as Day

Clear UV ink has the same advantages as color inks in that it can adhere to a wide range of substrates, is durable, is better for the environment than other printing methods and cures quickly. The ink’s clarity ensures great color saturation, making the graphics stand out without vibrance diminishing.

It can be used with printed work and UV direct-to-film as a finish or spot varnish. It can also create a variety of effects, such as adding a glossy highlight to a portion of a printed surface or adding subtle text overlaying an image. It can also add water-like visual effects on all or part of a print.