Combining UV printing and laser cutting is ushering in new opportunities for exciting acrylic finishes. In many ways, the dual processes are a perfect match: UV printing uses special inks that are cured with ultraviolet light, resulting in vibrant colors and sharp graphics. Laser cutting, meanwhile, allows for precise cuts through acrylic materials of any thickness, allowing you to create intricate designs and shapes that would be difficult—maybe impossible—to achieve with traditional cutting methods.

Dream Team: UV Printing and Laser Cutting

The combined processes provide new creative possibilities for acrylic—and lots

of opportunities to boost profits.

By: Jason Henninger

(Originally printed in the November/December 2023 issue of Insights.)

Combining UV printing and laser cutting is ushering in new opportunities for exciting acrylic finishes. In many ways, the dual processes are a perfect match: UV printing uses special inks that are cured with ultraviolet light, resulting in vibrant colors and sharp graphics. Laser cutting, meanwhile, allows for precise cuts through acrylic materials of any thickness, allowing you to create intricate designs and shapes that would be difficult—maybe impossible—to achieve with traditional cutting methods.

Trevor Wanamaker of Maker Experiment, a YouTube-based business that provides industry education, says the combination allows for a lot of creative freedom. “The ability to combine the two technologies is very helpful,” he says. “It definitely lets you do some unique things that you can’t do with each one by itself.”

Steve Weist, who oversees sales at PDS Equipment, says that if you aren’t combining UV printing on acrylic and laser cutting, you will not remain competitive for long. “All my most successful UV printing [clients] own lasers, and the laser companies that add UV printers are probably our most successful customer base because they understand machinery, and they understand precision,” Wiest says. “The laser companies all would benefit from UV printers, and every UV printer needs a laser. Perfect combination.”

Steve Weist, who oversees sales at PDS Equipment, says that if you aren’t combining UV printing on acrylic and laser cutting, you will not remain competitive for long. “All my most successful UV printing [clients] own lasers, and the laser companies that add UV printers are probably our most successful customer base because they understand machinery, and they understand precision,” Wiest says. “The laser companies all would benefit from UV printers, and every UV printer needs a laser. Perfect combination.”

Big Benefits

Beyond creating eye-catching designs, UV printing with laser cutting has additional perks, including:

- Fast production times: When UV printing combines with laser cutting, you can create high-quality products in a short amount of time. The fast, efficient process is ideal for bulk orders or tight deadlines.

- Versatility: The dual process allows for a wide range of applications, from signage and displays to personalized gifts and promotional items.

- Professional and polished finish: Laser cutting provides clean and precise edges while UV printing creates a smooth and glossy surface. Together, they give designs an impressive finish that’s both professional and polished.

- Cost-effective: The dual process requires minimal setup time and materials, making it a budget-friendly option for large or small projects.

- Eco-friendly: UV printing on acrylic uses eco-friendly inks and is a more sustainable option compared to traditional printing methods. Additionally, laser cutting produces minimal waste and does not require any harsh chemicals.

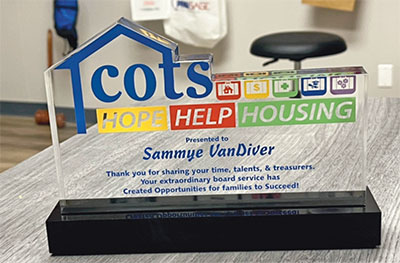

In general, when combining UV printing and laser cutting on acrylic, the possible applications are broad, allowing retailers to showcase their creativity. For instance, Mark Jaroh, owner of MJ Awards, used the dual processes to create a year-end gift for his son’s basketball team. “I took some three-quarter inch acrylic, cut it out and cut a base for it out of the same acrylic,” Jaroh says. “Then I UV-printed the team photo on the back of the acrylics and UV-printed

a basketball court on the base. When it was put together, it looked like the boys were sitting on the court itself.”

Some additional opportunities for combining the two processes include unique plaques and trophies for schools, clubs and company events; attention-grabbing signs for businesses; mementos and art objects for interior décor; promotional materials and corporate gifts; and commemorative items for special events (weddings, birthdays, memorials, etc.).

Mark Jaroh, owner, JF Awards, used UV printing and laser cutting to create a year-end award for his son's basketball team.

Cost and Space Concerns

While UV printing and laser cutting offer the potential for high profit margins for these unique outputs, the initial cost of the equipment can be steep. Space is always a concern whenever bringing in new equipment, as well.

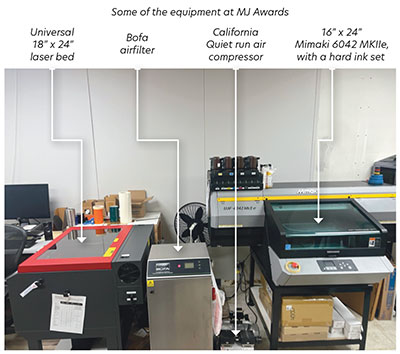

Jaroh says space limitations affected his decision to purchase equipment. The laser he ended up getting has a bed of 18" by 24", and the UV printer has a bed of 16" by 24". “I’m in an office building, so I have a small suite,” Jaroh says. “I was limited on what I could get for a UV printer and a laser. If I was in a little more spacious area, I definitely would have gotten larger versions of both.”

MJ Awards created a UV-printed award that utilized the school's colors

Jaroh uses a Mimaki 6042 and a 60-watt Universal laser. He added the UV printer to his shop about a year ago after hearing that his corporate clients wanted to see their logos in full color on acrylic awards. “The UV printer is an expensive machine, but it pays for itself just in the colorization of the company’s logos on awards,” he says. “It allows me to do personalized awards in full color for my clients.”

Clients have been very satisfied with the output from this combination, with one client nearly in tears because of how well the final product turned out, Jaroh says.

Learning Curve

Adopting any new equipment takes time and effort, but Weist feels that learning to combine these machines isn’t too hard once you know each one individually. “Each platform has a pretty steep learning curve,” Weist says. “To try to tackle both of those machines in one go wouldn’t be smart. You need to pick which one you feel is going to be the most profitable for you [to start].”

Learning to make them work together after mastering each on its own, however, is “a pretty easy transition,” Weist says. And, fortunately, acrylic is not a terribly expensive material to practice on.

Jaroh also emphasizes the importance of training. When he bought his UV printer from PDS, the people installing it also made sure he was familiar with its primary functions. “They did a fabulous job at explaining the basics,” Jaroh explains. “They didn’t leave until I felt comfortable enough to do a couple of simple jobs. I often tell people that when they get printers installed, they shouldn’t let the people leave until you feel comfortable turning it on, running a few jobs, cleaning it and [handling the] maintenance of the printer itself. That was the one thing I didn’t do with the laser, and I regretted it.”

To showcase a customer's logo, MJ Awards created a custom-cut acrylic product that was UV printed.

Beyond that initial introduction, there are plenty of free educational resources for newcomers and experts alike. Conferences and trade shows offer demonstrations and free classes on a variety of techniques, software and equipment. That includes APA’s upcoming International Personalization Expo in February, which features specific sessions on UV printing and another on laser hacks. Skills can also be honed through attending webinars or watching YouTube channels, like Wanamaker’s Maker Experiment page.

“If you’re going to have a product that combines both technologies, clearly lay out how you plan to attack it—kind of like an assembly line,” Wanamaker says. “You don’t want to be going from one side of your shop, cutting it on a laser and then walking to the other side of your shop to print it. The processes are so closely aligned and work together. Ideally, you want it where a product comes off one machine and you can put it straight on the other with minimal steps, process and setup.”

Some of the equipment at MJ Awards

Wanamaker also shares that planning is particularly helpful when you create many similar products. For example, if you have a lot of plaques that are the same size, all that changes is the design printed on them. Shops “can permanently set up their machine with a jig so that when placing items, it’s very quick to pull one off and put one on—and in the exact spot you need it to be. Anywhere that you can utilize jigs, anywhere that you can utilize a workflow process, it’s helpful.”

A wall sign for an office suite from MJ Awards made by laser cutting silver plastic and UV printing with a glossy top coat.

The opportunity to take advantage of jigs is something that Weist also recommends. “With UV printing on input, I can print a lot of small items,” Weist says. “With the laser, you can cut and produce your own jigs. Let’s say you’re printing on golf balls. You can just lay a golf ball on the bed to a fixture that holds it with a laser and make your own jigs.”

Learn More

Dive into more UV printing and laser cutting tips at the International Personalization Expo, Feb. 6-9 at the Paris Las Vegas hotel.