Over the past two years, the possibility to generate apparel revenue has become as strong as ever, thanks in part to so many customers starting small businesses, says Sue Wilcosky, marketing manager of Stahl’s Transfer Express.

The Perfect Fit

There are plenty of ways to begin offering apparel products, including producing everything in-house or outsourcing most elements of the process.

By: Matthew Blake

(Originally printed in the March/April 2023 issue of Insights.)

Over the past two years, the possibility to generate apparel revenue has become as strong as ever, thanks in part to so many customers starting small businesses, says Sue Wilcosky, marketing manager of Stahl’s Transfer Express.

For shops looking to break into the apparel industry, there are two main routes to pursue. On the lower-cost side, shops can focus on just one component of the garment process, like vinyl transfers or screen printing. This method allows retailers to field smaller orders and build up relationships with new clients while also creating opportunities to outsource work.

For the equipment ambitious—and those with a built-in market to sell large quantities of apparel—shops can also look to do all types of apparel work in-house.

Of course, the route you choose doesn’t have to be rigid. Lincoln, Nebraska-based Rixstine Recognition, for example, has made major equipment investments to make T-shirts, hats and other clothing. But, according to President Tim Hoffman, Rixstine will outsource a few jobs a year if the “customer has time and it’s a print that is specialized and the quantities are high enough.”

A key to entering apparel, Hoffman says, is being dynamic and flexible with customers’ orders. “It’s all about getting the customer the best price for what they are asking for,” he says. This requires a company to know what they can realistically do in-house and what must be contracted out.

Getting Started

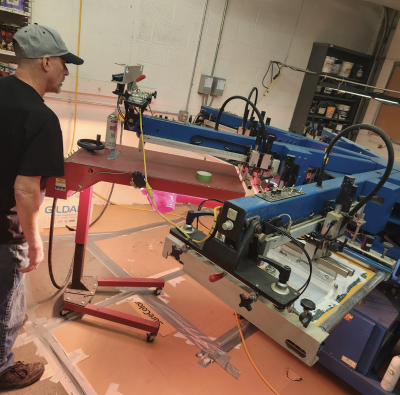

Rixstine Recognition's apparel process in action

Retailers can choose from any one of the following processes to get started with apparel: direct-to-garment printing, embroidery, screen printing, transfers, sublimation and more.

All of these processes come with advantages and disadvantages. Vinyl transfers, for instance, are low cost and great for producing small-batch orders, but the designs can fade over time. With screen printing, meanwhile, designs last a long time. However, the process can require more work space and involve more production steps.

A direct-to-garment printer has features like producing one shirt with 50 colors, Hoffman says, “But the equipment is high-maintenance, so you better have jobs for it, or it will be a doorstop.” In general, your potential customers and the types of orders they will request will help dictate the equipment you’ll need.

One low-cost entry point for retailers is to use the lasers that many in the industry already have. Greg Azorsky of KC Cool in Independence, Missouri, uses a CO2 laser to cut a vinyl material (Azorsky’s vinyl of choice is Thermoflex) into decorations that will go onto an apparel piece. Then, Azorsky places the decoration over the apparel on a heat press. (Azorsky also oversees the awards and engraving shop Recognition Plus.)

With this method, Azorsky advises simple designs with few colors. His rule of thumb is no order should have a quantity of more than two dozen. Those requests are too time-consuming because each laser decoration is done one at a time. He also says it’s too time-consuming to pursue an order with several colors, since a CO2 laser decorates one color at a time. Azorsky will outsource more elaborate orders to a business that owns a silk-screen printer.

In general, outsourcing some or most of the work can be a good starting place for apparel. Several companies, including Stahl’s Transfer Express, have a custom transfer business model. With Stahl’s, retailers send a custom design, with prices partly dependent on the number of color inks used.

Once Stahl’s receives the design, they make and ship the transfer paper back to the retailer. At that point, all the retailer has to do is put the design that’s on the transfer paper into a heat press. “We provide our customers with a no-mess, low-investment way to print apparel,” Wilcosky says, noting a business just needs a heat press to start.

To test if you’re ready for this type of outsourcing work, shops can start by designing art using software that’s often already in-house, such as CorelDraw. This may not instantly generate revenue, but it can be a way to test a concept and see if you have a talent for apparel design or have identified a demand in your local market.

Owning a particular piece of equipment that can handle larger designs, like a silk screen printer or an embroiderer, is yet another easy entry point, she says. “You find your niche,” Wilcosky says. Ultimately, she says, you want to become the destination for people seeking that particular niche.

All In

For shops looking to fully dive into the apparel industry, there are a lot of different equipment options. Screen printers, which require a big capital investment, are one of the most common. A manual screen printer tends to have up to four stations to insert T-shirts, sweatshirts and other apparel types. These machines require someone moving the garments from station to station. An automatic screen printer, which generally costs more, offers the advantage of more stations, with the T-shirts moving automatically.

Inside Greg Azorsky's KC Cool shop

The Planter Companies is the parent company of long-standing APA member Victory and its newer sister company, Classic Screen Print, which operates in suburban Chicago. The Planter Companies has invested well over $1 million on screen printing equipment with those resources sitting across the company’s 20,000-square-foot warehouse, says President and Owner Eric Priceman. This facility sits about six miles away from Victory and has over 20 employees. These investments include automatic and manual screen presses with over 10 stations, plus industrial dryers that emit infrared light to heat and cure garments. While his company has invested heavily, Priceman recommends proceeding with caution when buying more expensive machines unless you know exactly what type of order they will be used for. Priceman says many retailers who offer personalized products like awards do not have the space or desire to screen print or embroider. However, more than likely their customers are buying decorated apparel, but not from them. Priceman says his pitch is simple, “Classic Screen Print offers retailers the opportunity to offer apparel without the headaches and/or costs of production.”

Part of the issue is that while screen printers are the biggest capital investment, they are not the only equipment needed for apparel design. A somewhat standard job for Priceman can illustrate why. Priceman’s core clients are middlemen who sell to high schools and associations. As a hypothetical example, Classic Screen Print might get a T-shirt order to commemorate a high school volleyball team making a state tournament, or multiple garments for leagues and/or camps. To execute these orders, Classic has a full-service art department, a number of printers and a multitude of different software such as Adobe Illustrator, CorelDraw or Inkscape to make the design. Once the design is approved by the customer, it proceeds into production.

Stahl's transfer Express helps retailers outsource some of the apparel process.

The design will need transfer paper, an evolved form of carbon paper with the waxy feel of tracing paper. The paper is taped to the mesh screen at the bottom of the screen printer. The window-shaped mesh screens require a spray gun to clean.

Ink is squeezed or brushed onto the mesh screens to create the color design, with each screen getting a separate ink. With the volleyball T-shirts, for example, black ink for the volleyball nets might go onto one screen, white ink for the ball on another, red ink for the lettering declaring the team sectional champs onto a third screen and navy blue ink for the school’s name on a fourth.

The ink itself is often plastisol, a fairly viscous substance. But sometimes it is a water-based ink that can soak into the fabric as opposed to sitting on top of it.

Another moving part is the garment, which tends to come from wholesalers and is often referred to as apparel blanks. But increasingly they are not blank, and ordering the right garment is strategic. “At least 50% of shirts have a brand affixed to them,” Priceman says. “Everything today is brand. Nike, Under Armour, Puma. We have aligned ourselves with all the different distributors that can provide us those garments.”

Customer Care

Azorsky markets KC Cool by vending at city functions like special events at Kansas City art galleries and outdoor holiday gatherings. Much of his apparel is Kansas City-themed.

Wilcosky of Stahl’s Transfer Express markets at convention centers and expo halls. “We attend trade shows and are a large part of the education offered at those shows,” she says. Education is key. “Many of our customers are home businesses.”

Apparel designers, Hoffman notes, must also be nimble enough to change orders based on customer requests while also making it clear to them that there are limits to order adjustments. “Customers want to know how fast you can get it done, so be prepared for that question, and also be prepared for when they want another 20 shirts on a 1,000-piece order that you already did,” Hoffman says.

Rixstine Recognition can prorate the price of an additional 20 shirts if they have already run the garments, Hoffman says, though requests for different colors or design proportions necessitate a new order.

Also important is letting customers know exact turnaround times and ship dates, which helps provide clarity to employees to figure out work priorities and “makes a big difference to customers,” Wilcosky says. The need for speed is a constant challenge in the apparel industry. As Wilcosky says, “In the Amazon world, no one can wait.”

Should You Get a Screen Printer?

Sure, apparel design can be a complicated business that requires heavy capital investment and technical skills, such as knowing the right ink to use for certain projects. But it doesn’t have to be so involved, either. Companies can do smaller orders or focus on just one piece of the apparel puzzle, like decorating or design transfers.

For people looking to break into the apparel business, Eric Priceman of The Planter Companies recommends dabbling in the business first. “I would never suggest that people get into this kind of equipment without understanding it totally,” he says. Go with a third party first, Priceman says, and once the process is understood, invest in the equipment itself.

Kelly Walters, the marketing and events coordinator at Stahl’s Transfer Express, suggests getting started with a heat press. From there, a business can outsource making the ink-colored design or use a process like Therma flex on transfer paper to create the design.

Given the high cost, it might not make sense to get a screen printer unless customers are requesting multiple orders of dozens of T-shirts, hats or sweatshirts. Some customer bases, like large high schools or businesses, might provide incentive enough to buy a screen printer. But many do not. “Doing your research and understanding your customer base is the best way to be successful,” says Walters.

If demand to produce a lot of orders exists and you are considering making that capital investment, be sure to fully test out the screen printer (or heat dryer) before making a purchase. “The machinery at trade shows works great there, but it might not in your environment,” says Tim Hoffman, president, Rixstine Recognition. “Make sure to have them run as many tests as you can.”

Join Today and Invest in Your Business

When you become a member of the Awards and Personalization Association, you will receive access to the print and online editions of Insights Magazine along with many other valuable benefits. Explore how we can help you get connected with industry experts, increase your skills and knowledge through relevant learning opportunities, and save money with discounts for your business.

LEARN MORE

Read more apparel personalization articles