(Originally printed in the January/February 2023 issue of Insights.)

Personalization shops have been adding in-house rubber stamp making for many years. Shop owners have realized that producing stamps is an easy way to add a new profit center and expand the store’s existing customer base without a large equipment expense. This article will look at why a shop should start selling custom-made stamps and the most common methods for production.

How To: Utilize Your Equipment to Make Rubber Stamps

A look at two of the most common stamp-production methods.

By Casey Harp, Marketing Manager, Jackson Marking Products

(Originally printed in the January/February 2023 issue of Insights.)

Personalization shops have been adding in-house rubber stamp making for many years. Shop owners have realized that producing stamps is an easy way to add a new profit center and expand the store’s existing customer base without a large equipment expense. This article will look at why a shop should start selling custom-made stamps and the most common methods for production.

There are two basic reasons why an awards and engraving shop should add rubber stamp production. For starters, some (or all) of the equipment you already have on hand can be used in the stamp manufacturing process. Computers, design software and laser engraving units all can be used to make stamps. Therefore, purchasing additional equipment and employee training are kept to a minimum.

The second major reason to get into stamp making is that stamps will complement your existing product line. Awards and engraving shops are in the business of producing and selling personalized products. Most stamps contain custom messages that are specific to the user. Stamp sales are not only profitable as a standalone product, but they will also require the buyer to visit your shop, exposing them to your entire product line. This increased traffic through your store will result in sales of other items that you offer.

The most appropriate way to make stamps in your shop depends on the equipment you already have and the type of stamp images you wish to offer. The most common way is engraving rubber with a laser engraver. Another way to make a stamp is with a pre-inked stamp system, which creates a pre-inked stamp in minutes using a single light burst.

Before discussing these two methods, it’s important to note that these are not the only approaches to making stamps. In the past, stamps have been made by molding rubber in a vulcanizer or via laser printing and photopolymer exposure. Some stamp makers still use these processes, but both ways have been losing popularity recently because of modern technology.

Method 1: Laser Engraving

Just as laser engraving technology has changed the way that awards are produced, it is also having an impact on rubber stamp production methods. When properly set up, a laser engraving unit can be an efficient stamp production machine.

Engraved rubber sheet on laser

Suitable software is required for successful stamp manufacturing. Stamp printing characters should be “shouldered” or tapered from the base of the stamp to the face of the die. Some suppliers of laser engraving equipment supply the proper software with their machines while others sell it as an additional item.

Because laser engraving is accomplished by burning the item being engraved, the smell of burning rubber can become very strong when stamps are being made. Specially formulated rubber or photopolymer compounds are used, and many suppliers claim that their material has a “low odor.” Some may have less odor than others or have a scent component added, but none are odorless. It is helpful to vent the fumes outdoors, although your neighbors may not appreciate it. Ideally, an industrial filtering system using charcoal and other compounds should be considered as an addition to the laser engraving system when producing stamps.

The profit margin provided by sales of hand stamps or self-inking stamps should cause any awards and engraving retailer to consider adding such products. Regardless of the method used to make the stamp, the material cost of a hand stamp is rarely high, with retailers often seeing ROI of 300%-500%. Self-inking stamps, which typically cost a little more than a hand stamp, also fetch a similarly high ROI. Offering wholesale stamp services with a 35% or 40% discount to area printers and office supply dealers can quickly increase the volume of stamps sold, too. While the margin per stamp sold is smaller, overall profitability will be higher.

Stamp group: professional self-inking, standard self-inking, hand stamp

Method 2: Light Burst Pre-Inked Stamps

The most common piece of equipment for this type of stamp production is the Brother Stampcreator PRO system. The machine connects to a computer like a printer. Software provided is used to set stamp copy. All of the capabilities of your computer can be incorporated in stamp setup, including the use of resident fonts, scans and clip art. Templates are included for setting curved lines of type or circular format stamps. Borders and rules can also be incorporated in stamp setups.

The stamps themselves have a unique appearance. There are eleven sizes and four ink color options. The thermally imaged index on top is exceptionally crisp and clear. The printing die of the stamp is composed of high-density, micro-porous rubber that yields a flat printing surface rather than the customary raised printing surface.

Following setup, the stamp image is thermally transferred to an acetate cover sheet that the machine positions over the printing die of the stamp. The heat generated by an intense burst of xenon light seals the non-printing portion of the die so that ink can migrate through to the printing areas only. The ink gravitates into the printing die from a built-in reservoir that is contained in the handle. In an initial use, the customer can expect about 10,000 impressions from a stamp. It is completely re-inkable, with a life expectancy of 50,000 impressions.

This type of stamp is a great seller for customers in a rush or impulse buyers. The stamp can be made and used in as little as 10 minutes. From the customer’s perspective, this is a “no hassle” transaction—in the door and back out with the product in hand, all in one trip.

The Stampcreator PRO system is not a replacement for more traditional stamp production methods. It does not lend itself to convenient batch processing because the stamps are made one at a time. The stamp components are more costly than in other systems, so low-margin or whole-sale sales are less feasible. But the system is worthy of consideration in many stamp production settings.

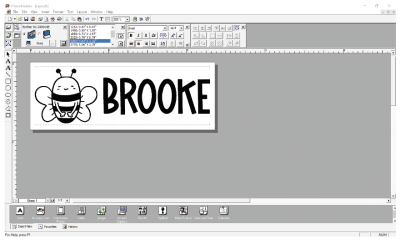

Brother Stampcreator PRO software screenshot

Look around your local market and see who is making stamps, then determine how your business might fit into the stamp production picture. Odds are that you will be pleasantly surprised by the opportunity that awaits.

Brother Stampcreator PRO system with pre-inked stamps

Suggestion:

The profit margin provided by sales of hand stamps or self-inking stamps should cause any awards and engraving retailer to consider addition of the product. Regardless of the method used to make the stamp, the material cost of a hand stamp is very low. The retail price for this type of stamp will vary, depending on the local market. Self-inking stamps will cost a little more in materials and retail for a higher price. Offering wholesale stamp services with a discount to area printers and office supply dealers can quickly increase the volume of stamps sold. While the margin per stamp sold is smaller, overall profitability will be higher. You’ll want to do your research to learn your particular market.

Join Today and Invest in Your Business

When you become a member of the Awards and Personalization Association, you will receive access to the print and online editions of Insights Magazine along with many other valuable benefits. Explore how we can help you get connected with industry experts, increase your skills and knowledge through relevant learning opportunities, and save money with discounts for your business.

LEARN MORE

Read more "How To" articles