Plastics might have a reputation for being tame or average looking, but that’s not the case anymore. Retailers are creating advanced plastic designs that can rival other finishes.

The Wild Side of Plastics

From jewelry to large wall décor, technology is pushing plastics to a new—and sometimes fancy—frontier.

By Caroline Heller

(Originally printed in the January/February 2023 issue of Insights.)

Plastics might have a reputation for being tame or average looking, but that’s not the case anymore. Retailers are creating advanced plastic designs that can rival other finishes.

“We’re always amazed at what our customers do with our plastic,” says Eric Hausserman, president of Rowmark. From custom jewelry to unconventional grape nametags for a wine shop to podium seals and command walls with cut-out decorations, retailers are getting creative with plastic, and saving money along the way.

“Where plastic was once considered strictly a signage material, it’s being used more and more for decorative projects and in design elements,” says Caitlin Tuohy, marketing manager, Johnson Plastics Plus.

Technology is shepherding in this new era. Dave Johnson, channel development manager at Gemini Inc., says he’s seen the potential for plastic products grow recently because

of new equipment in the industry. “In the past, it was just a rotary engraver, and you were literally and figuratively just kind of scratching the surface of the potential of plastics,” Johnson says. “Now, with a laser and UV printer, it’s almost unlimited what you can do.”

Versatile and Cost-effective

For retailers with limited equipment, plastic can be a great option because it doesn’t take a high-powered laser to cut it. “With the machinery we use, we aren’t able to cut some shapes in metal, so then we have to become creative,” says Sheila Kloski, president of B.B. Trophy and Awards Company. “And that’s where the metallic plastics really come into play.”

“Where plastic really helps customers is in the ability to fabricate it with just about any equipment they have on hand, from laser or rotary engraving to UV-LED and screen printing,” Hausserman says. “It also helps customers save time. For example, customers can laser mark metal using secondary marking sprays, but they’ll have to apply the spray and wait for it to dry before fabricating. There are engravable plastics that look just like real metal and can be laser cut and engraved without any additional steps.”

Plastic is often a cheaper material to work with, too, and it saves time in the long run. “There are some metals less expensive than plastic, but that’s going to be overcome by the labor involved in producing the material,” Johnson says. “Plastic is the least expensive option from start to finish.”

Made to Order

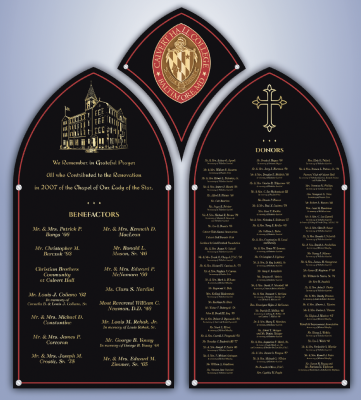

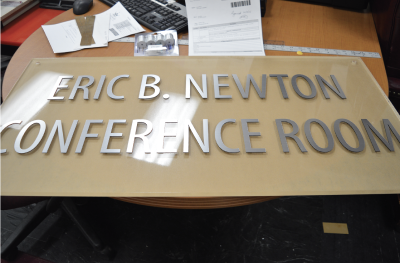

One overlooked benefit of using plastic, according to Amanda Gianotti, CRS, president of Allogram and Allogram South, is the ability to do really interesting customized products. Her company recently used plastic substrates to create a one-of-a-kind wall.

“We made a command wall from 4 feet by 8 feet black acrylic,” Gianotti says. “We don’t have any piece of equipment that can accommodate that large a size. But we were able to decorate it with cut-out plastic. The lettering was cut out of metallic gold plastic. You could do the same thing with vinyl, but it would be flat. What was nice about the plastic cut-out lettering is that it added depth and dimension.”

In addition to this large wall, Gianotti’s company has used plastic cut-outs to create more dimension on awards or logos. “We’ve used plastic accents on plaques and acrylics. For example, we have done logos or a state shape on a plaque,” says Gianotti. “You could sublimate that on a plate or engrave it on a plate, but you can also cut it out of plastic to give it more dimension.” Her company has also used plastic to create a lot of podium seals and even wall décor. “You can cut plastic or even layer different components on your piece to give a kind of mosaic look,” says Gianotti.

“When you’re doing things like this, you are creating products that a customer can’t just buy off the shelf or go online and find,” says Gianotti. “You’re creating a custom piece just for them.” The entire process, Gianotti says, shows how little plastic accents can go really far while also creating loyal customers along the way.

Getting Crafty

Plastic also offers retailers the opportunity to expand their product line. “We’ve witnessed a growth in customers who want to use plastic for craft projects, such as jewelry, stencils and custom home décor pieces,” Tuohy says. “Our new craft plastic and cast acrylic lines were developed with that in mind.”

Tuohy has seen customers make shapes and stencils with even small hobby cutters like ones made by Cricut and Silhouette. With some of their thicker plastic lines, Tuohy has seen customers make jewelry and home décor signs. “We’ve also seen customers gravitate toward combining plastic with other media, such as metal and wood, to make some really creative projects. They’re also using mounting hardware like standoffs to create dimension with their signs and display pieces for visual interest and depth,” says Tuohy. Rowmark has tricolor plastic options that allow for retailers to make three-color signs and name badges in a single laser pass.

When it comes to new product considerations, retailers can also get crafty by building three-dimensional personalized objects. One of the most creative things a client of Gemini Inc. did was an advent calendar. “We have a distributor in Iceland, and he created an advent calendar. But this was Iceland, and I think they like their beer,” Johnson says. “He essentially made a wine rack with slots for beer bottles. He used a product of ours that is a cast acrylic material. The material comes in a variety of colors, and it was really cool to see the way the light hit it.”

New Tags

Sheila Kloski, president of B.B. Trophy and Awards Company, remembers a distinct time when her shop used plastics to wow a customer. “A gentleman came to me with an old and not very crisp logo. I kept thinking we needed to do something more than just slap this on a square or oval name badge,” Kloski says. The grapes in the man’s logo stood out to her. “I kept looking at the grapes, thinking, ‘I know we can do something with those.’”

Her shop ended up using a wine-colored plastic that had white lettering for the badge. They were able to cut grapes out of plastic to add to the edge of the name badge. “We were able to add a little more depth to it. It drew your attention to it because it wasn’t just your standard name badge.”

In this situation, Kloski says it was helpful to think outside the box with how plastic products are normally treated. “Look at logos differently when you’re talking with customers and how you might be able to implement plastics into their logo,” Kloski recommends. “Maybe their logo has a lot of colors. If you don’t have access to sublimation or UV printing, don’t let that stop you. Depending on what kind of plastics you work with, you can choose colors that compliment that company’s image, and your work can go extremely far.”

With plastic, there can be some trial and error in finding the exact right settings depending on thickness, finish and more. Each material has its own characteristics and will require its own settings. “The amount of life left in your laser tube can also affect your settings,” says Gianotti.

Retailers should be aware of the risks of working with plastic, as well. “Make sure you have proper ventilation,” Kloski says. “It can be dangerous because you’re burning plastic, so be very mindful of the settings you are using.

Gianotti echoed that advice. “The challenge of vector cutting is the fact that you are using flame or fire, so you don’t want to leave that unattended,” Gianotti, says. “You have to watch what you’re doing and dial in your settings, so you don’t light the material on fire.”

After all, Kloski says, if you aren’t careful, you can end up with a burn residue that stays on the plastic if you don’t have the correct setting. Her advice? Practice on a sample piece first, and keep your eye on the product. Once you feel comfortable on those smaller works, then graduate to the pieces for clients. “The only way you learn is by trying,” Kloski says. The benefits far outweigh the risks, she says, and customers will appreciate a final product that is unique and goes beyond what they could have imagined. “You have to experiment, be willing to play around and test it out.”

Join Today and Invest in Your Business

When you become a member of the Awards and Personalization Association, you will receive access to the print and online editions of Insights Magazine along with many other valuable benefits. Explore how we can help you get connected with industry experts, increase your skills and knowledge through relevant learning opportunities, and save money with discounts for your business.

LEARN MORE