Change is constant. That’s something Karl Scheife knows well, witnessing the industry’s shifting landscape as he’s run Competitor Awards and Engraving, Inc., for more than 30 years now. Just look at what’s happened with recreational sports leagues, he says.

Riding the Wave

Karl Scheife has learned to adapt to all the changes this industry has thrown him.

By: Matt Schur

(Originally published in the September/October 2022 issue of Insights.)

Change is constant. That’s something Karl Scheife knows well, witnessing the industry’s shifting landscape as he’s run Competitor Awards and Engraving, Inc., for more than 30 years now. Just look at what’s happened with recreational sports leagues, he says.

“Between the city of Milwaukee and Milwaukee County, there used to be 100 softball leagues at least,” Karl says. “We would do awards for all of them. Between the two, they might not run five leagues anymore.”

It’s the same with bowling, he says. There used to be 70 bowling alleys, presenting plenty of awards opportunities. “There were good customers of ours that went by the wayside, and you can’t get them back. You’re not going to be able to sell awards to a bowling alley that closed.”

So he’s learned to pivot. To go with the change. “I’ve really looked to increase my sales outside the awards industry because I think that’s where there is longer-term potential,” Karl says. “We still do a lot of awards—we’re never going to not do awards. But if I concentrate on machine plates, industrial engraving or getting another sign shop, that’s long-term. If you can find decent specialty distributors that want to buy from you, they can turn into huge customers.”

With a good staff, Karl Scheife focuses his time on sales, the website and ordering.

It’s not just change in the industry landscape; Karl has weathered the rise of the internet, the 2008 recession, the pandemic and more. Overcoming these challenges has meant a constant evolution in his approach to the business, including investing in new equipment and even building his own website.

“My first websites were horrible,” he says. Over the years, he’s worked with different web designers to improve the sites, eventually getting to a point where he says his machine plate site is “great, and we get a ton of business from it.”

But, for all the shifts, certain things don’t change: the need to have good employees, to be active in the community and to keep growing as a business owner. All of this work, he says, “really is a learning process.”

Friend of a Friend

With five employees, Karl, like many retailers, handles the website, sales and ordering. “I don’t do a whole heck of a lot of employee supervision,” he says. “I’ve got a really good staff. I’m not constantly looking at schedules or making sure people are getting things done because they’ve all been super responsible, and they’re taking care of business. That frees up my time.”

Finding these employees has been a bit sporadic, including a new hire this year that happened by “sheer luck.” He was looking to hire someone to do mechanical engraving and wasn’t sure how to go about it.

“I was getting a haircut and told my hairdresser that I was looking to hire someone,” Karl says. “I told her that I was looking for someone with no experience so that we can train them. I explained that it’d be a great thing for a young person who is looking for a career path and trying to figure out what they want to do.”

Turns out, his hairdresser’s son, Mason, was in exactly that spot, having bounced around landscaping jobs in recent years. “He’s been here for a few months now and learning to engrave. It’s been unbelievably great.”

The last two employees he hired also happened via word of mouth when current employees posted the opening on Facebook. “Both of those times, I tried all the regular platforms—ZipRecruiter and stuff like that—and didn’t get far. I was reluctant to have friends working with friends at first. But they weren’t super close friends, so it’s worked out.”

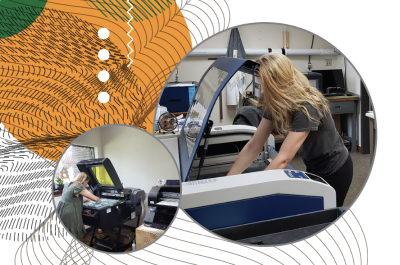

One of Karl Sheife's new hires at work

Karl’s looking to hire yet again as one of his employees, Emily, is pregnant and likely not returning. “I think hiring is probably the most difficult thing in the future. There was a time, at least in my market here, that if I offered someone $16-$17 an hour, you could have your pick. I don’t think that’s the case anymore. If you offer that money, no one applies.”

As a result, he’s looking into offering his first-ever work-from-home arrangement. “She’s super proficient in design. There’s a possibility she could be remote and send us her designs for the laser, sublimation printers and UV printers. I’m not at that point yet, but I’m figuring out if I might be able to do that.”

Growth Drivers

Competitor Awards is in its fifth location, this time sitting on state Highway 83 in Hartland, Wisconsin. The 3,600-square-foot standalone building houses Karl’s six CNC mechanical engravers, four CO2 lasers, one fiber laser and two UV printers.

Karl Scheife invested in two new pieces of equipment to meet rising demand.

He’s recently invested in a new fiber laser and UV printer, having seen both at APA’s International Personalization & Awards Expo. “For both products and equipment, there’s no place else you can see it all,” he says. “The show gives you a chance to see how things work. It’s invaluable. I mean, you’re not going to get a rep to drive out to your location, set up a UV printer and let you demo it for a day.” But the Expo provides that exact opportunity, he says.

The new equipment is part of what’s driving Karl’s recent growth, with his company increasing year-over-year sales by roughly 15% halfway through the year. Buying the new equipment, he says, was a way to “position myself to the point where, if you want engraving done, we are the place to go. A lot of places have gone out of business, and I want to make sure we can offer various services.”

In particular, Karl says that the fiber laser is one of the coolest pieces of equipment he’s purchased. Initially, he bought the laser strictly to engrave firearms, but he’s since found many uses for it. “It’s such a versatile piece of equipment that we use it all the time—there’s not a day that goes by that we don’t use it.”

When engraving products in the past, it’d take time to figure out how to hold the item, register the item and then engrave it. “It can be very time-consuming,” Karl says. “Recently, a customer brought in a baby spoon to be engraved. It was a very odd shape—it had a curled handle—and it could have taken us 10-15 minutes to get it into a vice, and I’d have to hold it firmly to engrave it. But with the fiber laser, we just put it in a piece of modeling clay, got it registered, hit laser and boom—it’s done. It’s really a great piece of equipment.”

Community Connections

Over 50% of Karl’s sales come from outside the awards space, with a lot of his work coming from industrial customers, including work for trailer manufacturers and agricultural implement manufacturers. “We do a lot of VIN plates for different manufacturers. We’ve been doing that since 2007. It’s really our bread and butter,” Karl says. “We have a lot of laser-engraved plates, kind of higher-end, durable plates. We do quite a bit of UV-printed plates and sublimated plates for indoor use. But all of that is for smaller manufacturers.

If you’re John Deere, and you’re making VIN plates for everything you make, you’re doing it in-house. But if there’s a trailer manufacturer, and they’re building 100 or 200 trailers a year, those are my customers.”

His customers are about a 50-50 split between national and local, with all the machine plates being national customers. “I think so many trophy companies have bought lasers and replaced their mechanical engravers, which seriously limits what they can offer. We’re still trying to be a complete full-service shop. We do a lot of local awards because people are starting to run out of the smaller trophy shops.”

With online marketing, Karl uses a combination of paying for a company that runs his SEO every month while also dabbling with Google Ads. “When we’re starting to slow down, I’ll spend a little money on ads. It’s a very effective way to get people to your website. In the last year, we had a big period of growth through the machine plates and organic traffic because of the SEO. We had so many requests coming in that I stopped paying for advertising.”

Equally important for sales—and also to stay connected to the community—is getting involved with local associations and people. At one point, Karl belonged to seven chambers of commerce. “I’m in an area that has a lot of smaller communities clustered together. I’ll be honest, I usually get awards just by joining chambers of commerce, and I usually get enough business to pay for a membership. But also, that networking, I’ve gotten a lot of local business off it over the years.”

He’s also been a member of the local Rotary Club for 23 years. Even though he didn’t join to increase business, it has. Plus, “My banker’s a Rotarian. My investment guy’s a Rotarian. It gives you a lot of contacts within the local business community. I’d certainly rather do business with someone I know and trust than throw a dart and hope the person’s OK.”