Sure, personalized tumblers make great gifts for teachers, parents or wedding parties across the country. But retailers are getting creative with what they engrave and personalize, including everything from whiskey and perfume bottles to the edges of coins, bomb shells and even cow patties.

Outside the Box

Getting creative—whether in the products you engrave or the way you source materials—can help pull in extra money.

By Caroline Heller

(Originally published in the September/October 2022 issue of Insights.)

Sure, personalized tumblers make great gifts for teachers, parents or wedding parties across the country. But retailers are getting creative with what they engrave and personalize, including everything from whiskey and perfume bottles to the edges of coins, bomb shells and even cow patties.

Pamela Deats Connaly, owner, Custom Built Awards, believes creativity is the answer to creating a robust company after COVID-19. “We’ve found through the pandemic that we’ve had to change stuff,” Deats Connaly says. “A trophy isn’t a trophy anymore. It’s whatever you make it to be. It no longer has a figure, a base and a plate. It may be a banner; it may be a piece of acrylic; it may be a piece of wood cut out in a shape with printing on it.”

Custom Built Awards is no stranger to more—let’s say—unique projects, including the aforementioned cow patty and a jockstrap and bra. “A lady brought me a jock strap and a bra and said they needed the most uplifting and supportive award,” she says. “I had to think out of the box and put something together.” Ultimately, she says, they created an award that exceeded the customer’s expectations. As for the patty, which was wrapped in plastic and sealed, Deats Connaly says: “We were able to make a really cool trophy out of it.”

When customers aren’t bringing in their own unique objects like underwear to engrave, Deats Connaly tries to proactively look for new items to engrave and personalize. “When you’re watching TV at night, you see trophies in the background,” she says. “I’m always looking for new opportunities.”

Such creativity doesn’t just extend to products—businesses across the country are getting inventive to overcome supply chain issues, as well. Overall, innovation is helping boost the bottom line. Custom Built Awards, for instance, was recently able to turn a profit from an idea that Deats Connaly saw on Facebook. “It was a piece we should have gotten less than three digits for, and I was able to get several hundred dollars for it,” Deats Connaly says.

Endless Possibilities

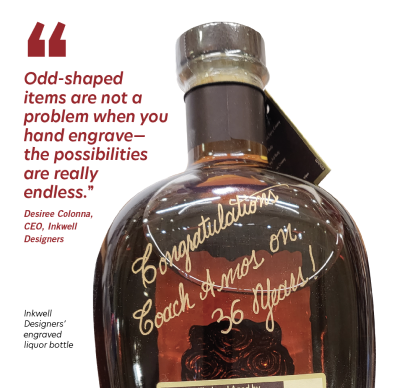

Desiree Colonna, CEO of Inkwell Designers, is always hunting for new opportunities. Five years ago, Colonna turned a calligraphy hobby into a successful business of engraving distinct objects. “I actually had a client who said, ‘You ought to be engraving wine and liquor bottles,’” Colonna says. “There’s a big need for that. I learned how to do that, and ever since, I’ve been traveling all over the world doing engraving.” Engraved liquor, wine and perfume bottles are now her most popular items, and Colonna has worked with companies including Marriott, Visa, Christian Dior, Saks Fifth Avenue and Bloomingdale’s. Hermés has even flown her to New York several times to engrave their products.

How does one hand engrave a whiskey bottle or a perfume bottle? With none other than a proprietary dental drill. “I use the same kind of drill that dentists use for false teeth and bridges,” Colonna says.

One of her strangest engraving endeavors was a bomb from World War II for a police officer’s retirement in Atlanta, near where her business is based. “It was a shell and inactive, of course,” Colonna says. “The benefit of hand engraving is I can engrave anything from the smallest object to something large. Odd-shaped items are not a problem when you hand engrave—the possibilities are really endless,” Colonna says.

She also has hand-engraved knives and jewelry. “The challenge is writing in a straight line. That’s the hardest part—making sure the mechanics are there and that you don’t get sloppy,” Colonna says. “It’s taken me five years to get where I’m at.”

About 50% of Colonna’s business comes from other methods of personalization. “I do UV printing, laser printing, leather embossing, hand engraving, painting; I do so much,” Colonna says. “Every day is something different.”

Taking a Swing

For businesses looking to expand the creative work they do, a slow and methodical approach can help—whether that’s gradually adding to a product line or investing in new equipment. For instance, Vince Frank, president of Catania Medallic Specialty Inc., likes to add one or two new products every couple of years to his company’s offerings. One product he added since buying the Avon Lake, Ohio, business 20 years ago is the Pop2Now bottle opener, a bottle opener that opens both bottles and cans. “We manufacture it, and I personally own the patent for this product,” Frank says.

Catania Medallic Specialty Inc. also engraves coin edges. “A couple of customers requested it, so we just kind of experimented to see what works and what doesn’t,” Frank says. “It was a little tricky engraving on the edge of the coin initially.” But soon, his company was able to figure out how to laser and rotary engrave coin edges. “Laser is just a little easier than rotary engraving, but you can rotary engrave them as well,” Frank says.

Deats Connaly, who has been in business for 43 years and grown Custom Built Awards from a 250-square-foot bedroom, partly credits her innovative approach and willingness to buy new equipment for her company’s longevity. “The classic plaque is evolving into something different than what it was. I believe you’ve got to stay up with the equipment to make sure you can make your product look like it’s worth a million dollars,” she says. One type of equipment Deats Connaly has invested in is direct print machines, or UV printers. “We’ve got direct print machines here, and we’ve learned all kinds of stuff that we can do with them to keep our products up to date,” Deats Connaly says. “You can print on anything.”

Investing in direct print machines is something that Susan Cox, president and CEO of LogoJET, knows a lot about. LogoJET sells direct-to-substrate printers. “I would say 75% of our customers also have a laser, so the pairing is becoming more popular and is extremely complementary,” Cox says. “We often say that when you can integrate laser with UV printing, it’s like peanut butter and jelly.” Catania Medallic Specialty Inc. is one of those companies that does both. “We direct print, as well. We use a LogoJET printer, which we have had really good success with,” Frank says.

Adding direct printers allows retailers to get creative with personalized products and do more work in-house. Cox sees her customers printing on a variety of objects. “We are seeing a lot of items for wedding gifts, like jewelry boxes, totes and even golf balls,” Cox says.

Surviving the Supply Chain

Responding to inventory issues and getting around the supply chain crisis is affecting all businesses, large and small. “The biggest concern right now is the supply chain,” Cox says. “It’s really hard to get products.”

One of her customers who engraves a lot of plaques has found a creative way to get around the low supply of metal sheets. “Inventory is very scarce, so one of my customers literally takes a blank slate—it could be white—and they UV print on it.” Instead of having to purchase 20 different laminates, they can purchase one kind. For example, customers don’t have to pay more for marble sheets, Cox says, but instead just download a marble background and print on it, saving a lot of money while also avoiding supply chain delays.

LogoJET customers are also getting creative with medallions, given the supply chain issues, Cox says. Customers can purchase a standard circular medallion and UV print whatever they want inside. “If you’re an advanced user, UV printing can do textures,” Cox says. She has seen customers print textures inside a medallion to mimic embossing with resin colors. “You can get really creative to fake different techniques,” Cox says. From sandblasted looks to color fills, UV printing is allowing retailers to be more creative and in control of their product when supply issues are a concern.

“With inventory the way it is, I’m fixing to invest in a bunch of new equipment,” Deats Connaly says. “I want to be able to cut things out and print on them so that I’m not in a box.”