Have you ever experienced a problem that took a good night’s sleep to figure out? Sometimes our brains need to roll the problem around in our unconscious for an answer. Sometimes it takes longer than one night’s sleep.

Brought to Light

Inspiration finally struck after years of trying to make a promotional bar light.

By Shon Roti

(Originally published in the July/August 2022 issue of Insights.)

Have you ever experienced a problem that took a good night’s sleep to figure out? Sometimes our brains need to roll the problem around in our unconscious for an answer. Sometimes it takes longer than one night’s sleep.

Three years ago, one of my clients gave me a project to noodle. He was looking for ideas for a bar light that can be used as a promotional product for Pendleton Whisky.

Figure A

But at that time, I was new to my role as a business owner, and bar lighting was certainly not something in my wheelhouse (or at least it hadn’t occurred to me that it could be). I had also done a great deal of searching online for a light I could modify or even emulate, but there was little to be found. So I put this project on the back burner and provided other products for my client that were more familiar to me and could be created in-house or easily sourced.

Over the years, I have provided this client with thousands of branded promotional products, developing a great rapport along the way. However, the bar light idea continued to simmer in the back of my brain, and it bothered me that I hadn’t found a solution. It was the one request from my client that I was unable to meet—until earlier this year.

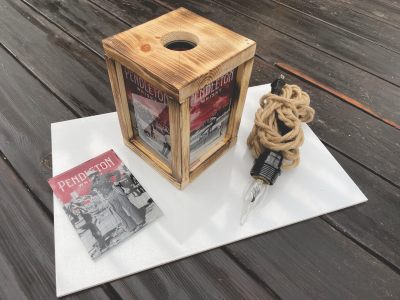

Sometimes it just takes finding that one element that creates the spark for the rest of an idea to come to fruition. Once I discovered sublimation acrylic, the idea quickly formed. This material could accept an image and still allow light to come through. The build started quickly. With a few items sourced from Amazon, a little woodworking and some help from my laser, sublimation printer and heat press, I was able to complete the prototype in Figure A.

The Build Overview

I started with the graphics. This was going to be key to the appeal, as it would be the construction focal point. The images had to create interest and fit the brand’s motif. I’m guessing that the marketing department in charge of this whiskey probably has a more detailed description about the themes surrounding the brand, but it may be best summed up with just three words: rustic, vintage, cowboy.

I started by searching one of my favorite image repositories, the New York Public Library Digital Collection (digitalcollections.nypl.org). This cache of nearly 1 million images was sourced from photos scanned from books within the library’s collection. I love this source for its almost limitless volume but also for its ease—no account setup is needed, and much of the content is copyright-free.

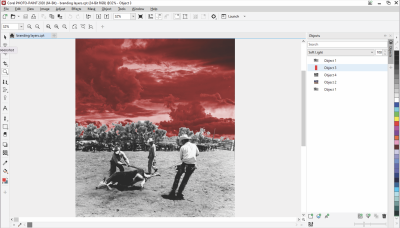

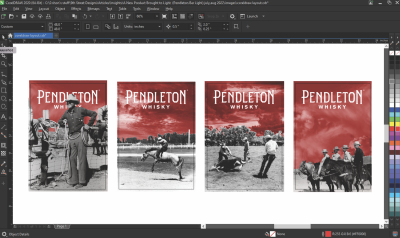

After downloading several images of cowboys doing their cowboy things along with some good sky images, I brought them into Corel Photo-Paint. I rendered the skies red to match the Pendleton logo color and mashed the vintage images with the red skies (Figure B). I then imported the finished image into CorelDRAW. The red sky would make a great space to place the logo (Figure C).

Figure B

Figure C

I used my laser to cut the acrylic into the appropriate sizes, then sublimated the images to the acrylic using the distributor’s instructions.

[!] hen sublimating the acrylic, the image will need to be printed “right-reading”, not reversed, as this image will be sublimated on the back of the product. Also, despite the ¼-inch thickness, the acrylic will tend to warp when removed from the heat press. Lay the acrylic on a piece of metal (image side down), and place a flat heavy object on top to reduce the warping. Ideally, another heat press (cool and not turned on) would be a great tool for this stage.

Figure D shows the raw material sourced from JDS (SAC1224), a cut and sublimated acrylic panel, light cord, flickering light bulb and the wooden cage housing the remaining panels.

Figure D

Figure E

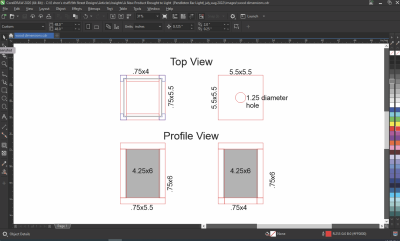

To create the wall sconce with the wooden lantern cage, there were a few tools needed for the project (Figure E): drill and drill bits, framing square, hammer, nails, screws, wood glue, screwdrivers, ear protection, tape measure, pencil, wood chisel bit (1-inch), spray paint, sanding block and paper, ¾-inch thick wood, circular hole cutting bit (1 1/4 inch). (Not shown: chop saw, belt sander and table saw.) I bought the light cord and flickering light bulbs online.

Figure F

Figure G

Before construction of the sconce and cage, I wandered online to find some ideas for the structure (Figure F). I modified and combined a few ideas and used CorelDRAW to draw up the construction schematics (Figure G). I then printed this to use as my guide during construction.

To be sure, there were a few snags during construction, and I had to improvise occasionally where I had overlooked some challenges. For instance, sanding the inside of the hole for the light took some noodling. I used the hole cutter wrapped in sandpaper along with the drill to get it smooth (Figure H).

Figure H

The Wood Finish

Part of the brand’s motif is a rugged/rustic look, so I knew that the accidental imperfections I created would appear as purposeful. Part of the bar light’s appeal is its distressed look. That took much of the pressure off me to make it perfect given my imperfect woodworking skills. In continuing with the light’s imperfect nature, I used a couple of techniques for the wood finish. The bracket portion of the light was spray-painted black and lightly sanded around the edges

to expose the bare wood. The cage/lantern portion was burned using a butane torch.

If you want a bit less labor in the construction, ¾-inch square wooden dowels can be sourced online.

In Summary

Every year there are thousands of new products created for our industry but most have a singularity in purpose. For instance, a sublimatable mug can only be a mug and nothing more. Sublimation acrylic, on the other hand, is a product that is more akin to a building block—a raw material that can become a part of an endless number of products that is limited only to one’s imagination.

After showing the prototype to my client, they were over the moon and excited to show their customers a new and unique promotional product.

Join Today and Invest in Your Business

When you become a member of the Awards and Personalization Association, you will receive access to the print and online editions of Insights Magazine along with many other valuable benefits. Explore how we can help you get connected with industry experts, increase your skills and knowledge through relevant learning opportunities, and save money with discounts for your business.

LEARN MORE