When engraving a trophy or customizing a gift, lasers are an obvious go-to. But lasers’ potential markets are almost limitless. For a retailer who is proficient with or willing to learn more about laser engraving, new markets and customers are yours for the taking.

The Niche Markets of Lasers

REACH NEW AUDIENCES AND DIVERSIFY REVENUE STREAMS

By Brian Stanley

When engraving a trophy or customizing a gift, lasers are an obvious go-to. But lasers’ potential markets are almost limitless. For a retailer who is proficient with or willing to learn more about laser engraving, new markets and customers are yours for the taking.

“Retailers can take advantage of the fact that personalization of everything seems to be a growing trend,” said Tom Tamburrini, general manager of Radian Laser Systems in Anaheim, CA. “Although it could fall into the category of gifts, the personalization of drinkware continues to grow at a fast pace. Retailers with good marketing skills will quickly find that their flatbed lasers are getting backed up with customized drinkware orders for individuals and corporate customers alike.”

James Stanaway, director of marketing for Epilog Laser of Golden, CO, agreed.

“The great thing about the laser is that you have a tool that can expand into so many different areas,” Stanaway said. “Awards and gifts are just the tip of the iceberg when it comes to laser engraving/cutting applications. For a successful business, it really comes down to diversifying your product line, increasing your offerings to current customers, increasing your revenue, or expanding your client list with additional products.”

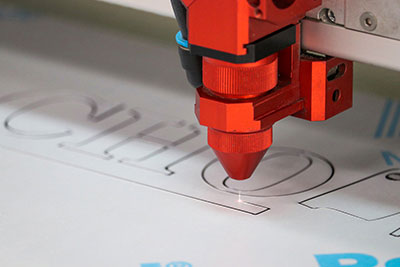

Indoor and outdoor signage, industrial marking (like asset tracking), and other business-to-business opportunities can be lucrative sources of income, according to David Stevens, industrial applications manager at Trotec Laser in Plymouth, MI.

Photo courtesy of Trotec Laser

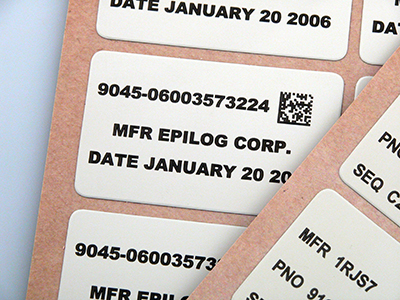

Industrial marking is a “fantastic market engravers can tap into for several reasons,” Stanaway agreed. Popular industrial marks include bar codes, serial numbers, 2-D data matrix codes, and logos on products. These marks can be used for identification, tracking, quality assurance, branding, and asset protection.

Manufacturers often need to brand or serialize many identical parts, so engravers can easily load up their engraving bed or jig and enter the variable data to mark an entire table of tags, parts, or tools—a profitable highvolume job.

“Also, industrial jobs are often more consistent than oneoff projects,” Stanaway said. “Manufacturers may need to mark parts or components on a regular basis—monthly, quarterly, semi-annually, etc. Getting these products into your regular rotation of jobs can be an ongoing revenue generator for your business.”

Photo courtesy of Trotec Laser

Photo courtesy of Epilog Laser

SEARCH FOR CREATIVE OPTIONS

Stanaway suggests that retailers examine businesses in their area and market themselves in creative ways.

“In Colorado, we’ve seen a lot of breweries and distilleries open over the years,” he said. “These businesses sell and give away a lot of swag to build awareness of their beverages—think promotional products like coasters, growlers, pint glasses, mugs, and water bottles. These businesses rely heavily on exposure, and their logo should be on everything going out the door,” he said.

Schools using identification tags and other signs are a great target for engravers, as are Realtors who need home décor and closing gifts, Stanaway said.

Another common use for lasers is jewelry engraving. Jewelry engraving used to be the domain of rotary (computerized) engravers because CO2 lasers don’t mark bare metals without the use of a metal-marking compound. But fiber lasers make it possible for retailers to service the jewelry engraving market without learning how to diamonddrag engraving.

“A retailer with a fiber laser should be able to access this market quite easily and develop a customer base that will be coming back for years to come,” Tamburrini said.

Photo courtesy of Epilog Laser

Fiber lasers aren’t a one-trick pony, either. “Looking at things with a longer-term view, industrial applications are clearly a way to expand and create some alternative revenue channels. Fiber lasers can be used to serialize machined parts, create identification plates, remove coatings, clean oxidized parts, or polish parts.”

If you have a CO2 laser, like most Awards and Personalization Association members, you can still capture this business. “CO2 lasers can be used in many of these applications as well,” Tamburrini said. “Acrylic cutting applications have existed for many years and will continue to do so forever.”

Lasers are also capable of specialized applications, such as automotive features and firearms, Tamburrini said.

“One of our customers has started using their fiber laser to manufacture and customize shift knobs. This is certainly a niche application, but it shows the creativity and resourcefulness of some APA retailers. Others have used their laser to customize under-the-hood parts such as valve covers and air intake tubes,” Tamburrini said. “Fiber lasers can be used by firearm manufacturers for serial number engraving, but the bigger market for APA retailers would be in the customization and personalization of handguns and rifles by engraving images and patterns on the guns to create the one-of-a-kind products that customers enjoy.”

Photo courtesy of Epilog Laser

UNEXPECTED SITUATIONS

Personalized, unique items are meant to be treasured for years. But lasers can also be used to customize or create temporary products and items needed quickly for unexpected situations, such as the COVID-19 pandemic.

“The industrial markets, and more specifically anything related to medical tools and technology, were able to continue their operations with little interruption during the pandemic, and many even saw increases in production,” Stevens said. “This mainly revolved around product marking for tracking purposes. Many signage companies were also able to keep their doors open, specifically for the need for handwashing, face mask, or social distancing signs.”

In the pandemic, lasers have been used to create face shields, acrylic barriers to protect front-line workers and students, and COVID-specific signage. “It seemed like overnight we saw businesses large and small that suddenly needed a variety of directional and way-finding signage to inform patrons of their protocols during the pandemic,” Stanaway said.

Overall, Stanaway believes signage is probably one of the most profitable alternative applications for engravers expanding beyond awards and gifts. “Regardless of industry, everyone needs signage—room numbers, maps, point of purchase displays—and with so many laser-friendly materials on the market, having a laser allows you to create striking signage for any environment,” he said.

UNLOCKING OPPORTUNITIES

Some retailers can meet their customers’ needs with an entrylevel laser system, but the more laser accessories and features you have, the more potential you unlock, Stevens said.

“For example, when processing signage or preprinted materials, having a camera registration system added to your laser will enable you to make clean cuts around printed graphics. These capabilities can be beneficial when offering services to print service providers that create detailed signage or point of purchase displays,” Stevens said.

Photo courtesy of Radian Laser Systems

Purchasing a fiber laser system or adding a fiber laser source to your CO2 system can allow you to fulfill jobs that require direct marking and engraving onto blank metals or creating a color change on plastics, which is ideal for industrial marking opportunities, Stevens said.

Luckily, your CO2 laser has a lot of potential for marking so many kinds of materials. “We all know the versatility of the CO2 lasers and their ability to work on wood, acrylic, textiles, and much more,” Stanaway said. “You can quickly move into these additional product offerings by only investing in the materials needed to create the products.”

“If you’re not already working with cylindrical items, like wine bottles and tumblers, you’re going to need to add a rotary attachment to your system. This allows you to engrave all the way around the item and create really stand-out products for customers. Most customers opt for the rotary when they purchase their system, but if your system doesn’t have a rotary option, it might be time to upgrade,” Stanaway said.

Rotary adapters are popular across brands. “If you have a flatbed laser and want to mark drinkware, you will need a drinkware rotary adapter,” Tamburrini agreed. “If they have a 3-D galvo laser, then they can do single-sided drinkware marking with something as simple as just a work-holding jig. If they want to mark multiple sides or do full wrapping, then they would need some type of rotary device in either case. Jewelry marking is another example where a good rotary device is needed to properly mark around curves and for properly holding the part to be engraved.”

WHICH LASER TO CHOOSE?

For industrial marking, the type of machine or process used varies by material and type of mark needed. A CO2 system will engrave coated, painted, or treated metal products

such as anodized aluminum, but bare metals must be coated with a metal marking agent (such as Enduramark, CerMark, or LaserBond).

The heat of the laser bonds the solution to the metal, resulting in a permanent mark. It’s an easy process but adds time and nominal cost to the job, Stanaway said. “

Additionally, in this process, no metal is actually removed from the piece, so there’s no depth to the engraving. Fiber lasers, on the other hand, will mark bare metals with no pretreating required. They can also achieve depth of engraving as well as polished and annealed looks, depending on what laser parameters you use,” Stanaway said.

Fiber systems are more specialized and limited in the materials they work with, so if you expand to offer industrial marking services, you’ll want to consider what your customers need and whether it will be more cost- and time-effective for you to purchase a fiber laser or to use metal-marking compound with a CO2 laser.

“A (CO2) laser engraver or cutter is always a smart addition to a retail shop because they can process a wide variety of

materials to meet a large number of demands in various industries,” Stevens said. “Not only can they help you improve production efficiency, lasers can increase product value and selling prices, and offer versatility to broaden product lines to meet new market needs—improvements that could be crucial to remaining profitable in an uncertain business environment.”

It’s a good time to purchase a laser, “especially as we start to come out of the pandemic,” Tamburrini said. “Many of my customers are expanding now to keep up with the growing demand for items created or improved by lasers. We have never seen the kind of interest in lasers that we are experiencing now.”

In addition to being able to satisfy new demand, lasers on the market today may surprise even long-time laser users. “Lasers are so versatile and becoming more and more user-friendly,” Stanaway said. “There are all kinds of new and fun laser-friendly products and materials popping up all the time. Having a laser allows retailers to reach new audiences and diversify revenue streams, and that’s always a good thing.”

Are You Enjoying Inside Insights?

We invite you to explore more Awards and Personalization Association benefits. When you become a member, you will gain access to additional Insights Magazine articles along with innumerable resources that will help your business.