As a promotional products retailer, I find joy in producing and sourcing a wide range of products, including some that are unconventional or unfamiliar to me.

Thinking OUTSIDE the Custom Package

Use Laser Cutting to Quickly Create a Custom Project

by Shon Roti

When I was asked to producer

a box like the one in FIGURE A, I assumed the task would be a relatively easy one. It was not. The journey to get to the final product was fraught with challenges, but I learned valuable lessons about myself and my equipment’s capabilities.

Figure A

When you have a good customer in this business, it may go without saying that it is a good idea to work to keep them. Saying “no” to a good customer is rare for me and only occurs when I have exhausted all ideas and options.

When my good customer—a restaurant and wine bar owner—inquired about getting a quick turnaround for the custom packaging for a “12 Wines

of Christmas” promotion, of course I agreed. Until that moment, however, packaging had not been something I had considered as a potential revenue stream, and I was not even sure where to start looking for the product.

Naturally, when I think a product is out of my wheelhouse of expertise or cannot be produced in-house, I look to my network of wholesalers for help. But I was striking out left and right with this project. I was confronted with options that were cost prohibitive and included long production times or finding product offerings that were not exactly what my client wanted.

Then I caught a break.

I had left some messages with a few local packaging suppliers, and after some referrals and a few more phone calls and messages, I found a company that could make a custom box that could produce the product based on the client’s sample box dimensions. This was a big relief, as the client’s deadline was getting closer. But after getting a quote from the supplier the next day, I realized their production date had changed from our initial conversations. The delay was caused by the need to special order the material for the partitions on the inside of the box. Not good.

I was in a pickle, for sure. The delay would move production past the client’s deadline, and it was too late to start over and look for a new supplier.

Necessity is the mother of invention.

As I sat and stared at the sample wine box my client had given me, I weighed my narrowing options. Then the idea hit me: I could use my laser to cut my own partitions.

After letting the local box maker know that I would only be needing the outer box made, I started shopping for materials that I could place inside my laser. I found a wholesaler for 12-in. x 18-in. chipboard pads—the kind of pads used to stiffen the inside of a shipping envelope (FIGURE B). The thickness was .022 in.—just sturdy enough to keep the wine bottles from banging into each other but thin enough to be easily cut with my 30-watt laser. I placed an order for a case of 420 chipboards, and they were on my porch the next day. Crisis averted.

Figure B

Producing the partitions in-house gave me a big window of time to complete my part of the product while I waited for the outer box to be produced by the local supplier.

I decided to take a little extra time to customize the partitions with the client’s logo. This would be an extra touch that would not take much more effort on my part but would certainly be an unexpected bonus for the client.

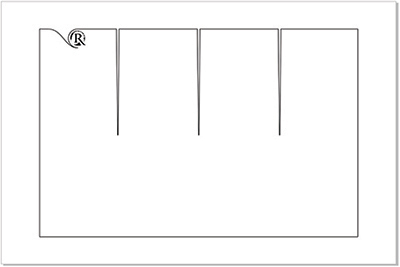

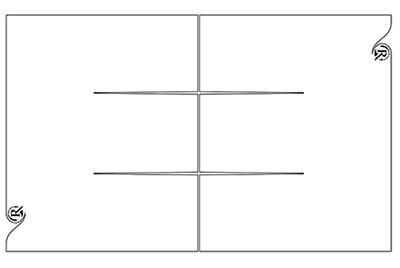

After some measuring and CorelDraw pen tool work, I managed to create the partition designs—two long and three short partitions, each with the client’s logo (FIGURES C and D).

Figure C

Figure D

Next, I placed the chipboards in the laser and began the process of experimenting with the raster and vector settings to create the best imprint for the logo and find the fastest, most effective speed.

Once the settings were dialed in, I let the laser run 500 partitions for about 9 straight hours while I assembled the completed partitions (FIGURE E).

Figure E

The last embellishment for the boxes was a sticker with the client’s logo to adorn two sides of the box. Again, I would normally find a wholesaler for this type of product, but

the turnaround time did not allow for outsourcing or more potential production delays. Fortunately, this product also could be created in-house with my sublimation equipment. The material used was a self-adhesive sublimation material that has similar properties to a sticker and can be custom cut.

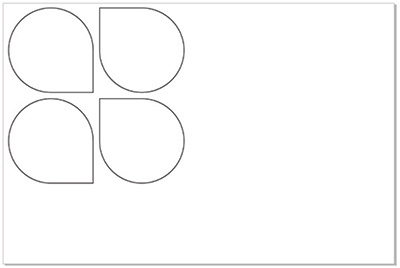

I created two files—one for my laser and one for sublimation (FIGURES F and G).

The lasering and sublimation production took about an hour and a half. At this point, I was well ahead of schedule for my part of the project and only needed to wait a few more days for the outer box to be produced.

Figure F

Figure G

Once competed, I had delivered the product to the client on time and above expectations. The boxes were then photographed for a feature news story to help promote the restaurant’s marketing campaign, which had already begun preselling the 12 Wines of Christmas bundles.

There is always a risk involved when a customer asks for a product or service that is unfamiliar or outside of a typical business model, and failure to produce what is promised is never a fun result for me or the client. However, without some risks, there are less rewards. A calculated risk is worth taking, and in this instance, I learned some valuable lessons. I pushed myself to further understand my laser’s capabilities, found a new vendor for future packaging materials, and added custom wine boxes to my product repertoire.

Shon Roti is the owner of 9th Street Designs, a sublimation and graphic design consulting and promotional products business. A graphic designer, Roti has spent more than 2 decades working as a production artist and instructor in the awards and promotional products industry. In 2014, the Awards and Personalization Association named him

Speaker of the Year. Find him at 9thsd.com or contact him at shon@sublimationconsultant.com.