When Insights refers to a laser, a CO2 laser is usually what we mean. That’s because CO2 lasers were the first on the scene in the personalization industry and have remained the dominant laser type in retail shops. But fiber lasers are fast gaining ground for a good reason.

Laser vs. Laser

By Julie Rogers

CO2 or Fiber?

When Insights refers to a laser, a CO2 laser is usually what we mean. That’s because CO2 lasers were the first on the scene in the personalization industry and have remained the dominant laser type in retail shops. But fiber lasers are fast gaining ground for a good reason.

CO2

Carbon dioxide lasers were invented in 1964 and introduced to the personalization industry in the late 1980s. A type of gas laser, CO2 lasers send an electric current through carbon dioxide (the active gain medium) to create coherent light. They offer the highest power available from a continuous wave laser.

The list of substrates you can engrave, cut, or mark with a CO2 laser is extensive, covering everything from acrylic and mylar to leather and wood. (See two leading suppliers’ lists at epiloglaser.com/how-it-works/laser-material-compatibility.htm and troteclaser.com/en-us/faqs/laserable-materials.) The notable exceptions are some plastics, ceramic, and bare metals. Without the use of a metal marking compound, a CO2 laser won’t mark metals that aren’t coated. “When a CO2 laser marks anodized aluminum, the laser ‘bleaches’ the dye from the anodizing to expose the color of the bare metal,” said Bob Henry, Epilog Laser product manager. “With powder-coated metals, the laser removes the coating to expose the metal, creating nice contrast.”

Photo courtesy of Epilog Laser (EpilogLaser.com)

CO2 Laser Advantages

- A very wide range of materials can be engraved, marked, or cut, including thicker substrates

- Help, resources, and application settings are easy to find because of this laser’s long history and industry popularity

- Purchase price is typically lower than for other types of laser

Fiber

“Fiber laser are relatively new technology following and generally supplanting YAG (yttrium aluminum garnet) lasers that have been used for industrial applications for decades,” Henry said.

The inability of CO2 lasers to directly mark or engrave metals created a need for the capabilities of YAG and fiber lasers (or fibre lasers, depending on where you live). Though fiber and CO2 lasers were created around the same time in the early 1960s, fiber lasers weren’t developed for commercial use until decades later and didn’t make their debut in the personalization industry until relatively recently. The active gain medium for fiber lasers is an optical fiber doped with rare-earth elements. The fiber provides optical gain in the same way the carbon dioxide does in a CO2 laser.

A huge advantage of the fiber laser is that it can be used to mark materials that a CO2 laser can’t: most metals, whether they are bare, coated, or painted; ceramic; and many plastics and polymers. With a fiber laser, you won’t need to purchase or apply metal marking compound to achieve high-contrast markings on bare metal.

Photo courtesy of Epilog Laser (EpilogLaser.com)

Fiber laser advantages

- Most bare metals, ceramic, and plastics can be marked, even those that can’t be processed by a CO2 laser

- No alignment or focus adjustments are needed, even if something inadvertently knocks into the machine

- No routine maintenance is required; lower lifetime cost of ownership

- High electrical efficiency can reduce energy costs

Why no mention of cutting power?

Analyses of fiber lasers used outside of our industry may discuss what thicknesses of metal are easiest and fastest to cut with a fiber laser. Why isn’t it included above? “Higher wattage CO2 (200-plus watts) and fiber lasers (100-plus watts) will cut metals but not at the wattage levels typically used in the personalization industry,” said Epilog Laser Product Manager Bob Henry.

Desktop or Freestanding?

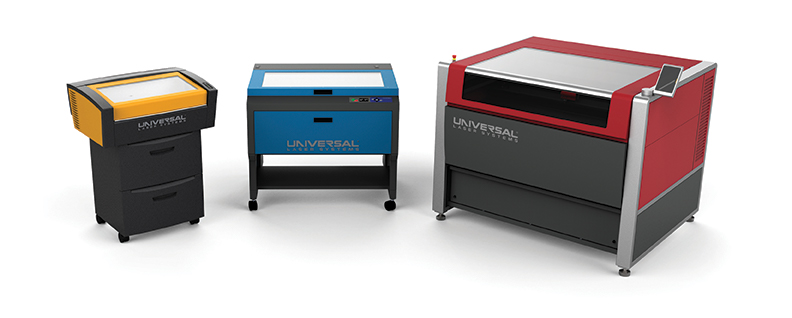

Laser systems aren’t small, but many manufacturers offer various sizes of systems, including models that can sit on a desktop and freestanding systems. An optional stand is offered for some desktop systems to create a hybrid experience.

Desktop laser advantages

Photo courtesy of GCC (GCCworld.com)

- Floor space won’t be taken up by these machines, which can operate off of a desk in the production area or even a counter next to a register

- Some desktop lasers have simpler operating software to create a better experience for new users

- Narrow doorways aren’t an obstacle to getting these machines into your business

- Lighter weight and portability offer the option of onsite personalization services at fairs, competitions, and other offsite events.

- Good backup option for smaller jobs when a freestanding machine is always busy

- Purchase price is typically lower than freestanding machines

Freestanding laser advantages

Photo courtesy of Epilog Laser (EpilogLaser.com)

- Desk space won’t be taken up by these machines

- Usually available with higher power levels than desktop versions, ensuring the necessary power for more jobs

- Designed to be used in more demanding production environments

- Wide variety of accessories available to further extend capabilities

- Larger table sizes available to allow for engraving of larger items and substrates

Want the best of both worlds?

Some laser manufacturers sell add-on racks designed to hold up their desktop lasers; This would enable the laser to function as a freestanding piece, when needed, while still remaining easy to take offsite.

Or, if you want a larger table size and more power, you can opt for a freestanding laser with lockable wheels for a bit of added mobility.

Gantry or Galvo?

Gantry

Also known as flatbed or XY plotter systems, gantry systems are the type of laser system typically used in the personalization industry. These lasers—which can be CO2, fiber, or another type—move the beam over the stationary object they are engraving or cutting. This also is referred to as “flying optics.” The beam is always directly over the area it’s marking. Typically, gantry laser systems are rectangular, with the engraving area’s length much longer than its height.

Photo courtesy of Universal Laser (UniversalLaser.com)

Gantry laser advantages

- Larger items can be engraved than typically can be handled by a galvo laser

- Thicker materials can be processed and cut

- Can engrave continuous artwork on larger areas without distortion

- Job setup is relatively simple, from software to material placement on the laserbed, making it ideal for handling a wide variety of jobs throughout the day

- Purchase price is typically lower than galvo machines

Galvo

Galvo (short for “galvanometer”) systems tend to be an upright rectangle shape (with the engraving area’s height being longer than its sides). Instead of having the laser beam move around the substrate, the beam is stationary and its light is directed where it is needed by a system of mirrors. Like gantry systems, galvo systems can be CO2, fiber, or another laser type.

Photo courtesy of Radian Laser (RadianLaser.com)

Galvo laser advantages

- 10–65 times faster than a gantry machine

- Excels at repetitive jobs thanks to high speeds

- Customizable for specialized uses or integration into manufacturing lines

- Focus tolerance is high, resulting in better marking on materials that aren’t flat

Enclosed or Open?

Enclosed

This is the typical laser system used in the personalization industry. The user opens a door to place the item in the system, closes the door, and runs the laser. The size—including height—of the item that can be engraved, marked, or cut is determined by the size of the laserbed (gantry) or marking area (galvo).

Photo courtesy of Universal Laser (UniversalLaser.com)

Enclosed laser advantages

- Job setup is usually simpler, meaning learning to use the machine is typically easier

- Many resources are available for support due to the prevalence of this type of system

- Systems are available from many industry suppliers, allowing for more choice

Open

Available open laser systems include a system that can be wheeled over a large or tall object and gantry systems with the housing removed to accommodate larger items. The systems aren’t open in the sense that the laser beam can put users at risk; instead, the area for marking is open, allowing for a greater range of substrate sizes.

Photo courtesy of AP Lazer (APlazer.com)

Open laser advantages

- Tall and large items can be processed, from furniture to headstones, in addition to the normal capabilities of a closed system

- Larger items don’t have to be disassembled for engraving, which decreases work time and risk of damage to the product

- In the case of wheeled systems, the machine can be wheeled over the substrate, reducing the number of times a heavy substrate must be lifted

- Purchase price may be lower than for enclosed machines. “Class II (enclosed) laser systems are usually more expensive than open (class IV) laser systems,” Henry said.

Dual-Source: Manual or Automatic?

The most common dual-source lasers in the industry combine CO2 and fiber lasers in one unit. “Dual-source” can refer to systems that combine other types of lasers, but for this comparison, we’ll use the term to mean a combination of CO2 and fiber.

Manual

This dual-source machine offers both laser types, but not on the same job. Instead, an item must be marked with one laser first. When that job is finished, the operator must switch out the laser source and optics before running the next part of the job with the other laser source.

Manual dual-source laser advantages

- Purchase price is typically lower than automatic machines

Automatic

This dual-source machine switches between the laser types without the operator having to be there to make the change. That means a product that needs to be marked with both lasers—like a knife that needs to be engraved on both the wooden handle and the bare metal blade—could be engraved in one job despite requiring two laser types.

Photo courtesy of Trotec Laser (TrotecLaser.com)

Automatic dual-source laser advantages

- Industry suppliers offer these machines, meaning there is trusted support available from the manufacturer or distributor

- Jobs can be run from start to finish while the operator works on another task

- Automatic switching reduces potential for user error

Surface or Subsurface?

Surface

This is the standard laser used in the industry—whether CO2 or fiber, desktop or standalone, gantry or galvo. These lasers alter the surface of the material being processed.

The laser beam, of course, can travel through clear materials, meaning it’s supposed to only alter the surface but could travel farther than it is meant to. That’s why lasering clear substrates requires the use of masking materials. That way, when done correctly, the laser beam stays on the mask, cutting only through the thin mask and then just to the surface of the substrate below.

Photo courtesy of Epilog Laser (EpilogLaser.com)

Surface laser advantages

- Relatively simple software and operation

- Popularity means there are many suppliers to choose from and resources to learn from

- Consumers are familiar with the concept of surface engraving, minimizing the amount of education you have to provide to create demand

- Lower purchase price, typically, than subsurface laser systems

Subsurface

Subsurface laser engraving (SSLE) focuses the laser beam into a transparent substrate (like crystal, glass, or acrylic) to “engrave” the interior by creating tiny fractures. The results are artwork and/or text that appears to be three dimensional within a smooth substrate. Originally used to mark the interior of liquor bottles to combat counterfeiting, this technology’s use in the personalization industry was patented and heavily protected. During that period, users paid a licensing fee for permission to use the technology. This hindered both the popularity of the SSLE among retailers and the development of new SSLE systems among industry manufacturers. The patent has expired, but there still aren’t a host of SSLE system manufacturers and suppliers despite consumers’ interest in the SSLE-personalized products. The type of laser used in SSLE systems varies by manufacturer.

Photo courtesy of Crystal D (Crystal-D.com)

Subsurface laser advantages

- Relatively few retailers have these systems, meaning there is less competition for customers and more opportunities to take outsourced SSLE work from retailers who don’t have an SSLE system

- The wow factor—consumers don’t see this technology as often, making them more likely to stop and examine samples

- Can be paired with surface engraving, color fill (on surface engraving), and even UV printing for complex combinations consumers won’t find elsewhere

What About...?

Water “lasers”?

Not true lasers at all, a “water laser” is a waterjet cutter. Awards and Personalization Association member supplier WAZER offers waterjet cutters at a price point and size that make them accessible to smaller businesses like our retailer members’. The WAZER machine cuts though many materials, including metal, stone, ceramic, composites, plastic, rubber, and foam.

Photo courtesy of WAZER (Wazer.com)

“Glass” lasers?

Rather than a separate type of laser, “glass laser” refers to a type of tube in a CO2 laser. Most CO2 laser systems use glass or metal tubes. The glass and metal tubes use a different type of electric current and a different cooling system, in addition to offering different benefits.

MOPA lasers?

Master oscillator power amplifier (MOPA) lasers are a type of fiber laser that is a relatively recent, exciting development. With cutting-edge technology, reliability, and efficiency, MOPA lasers even make it possible to color mark some metals, plastics, and acrylics by altering their speed and power levels. Some industry suppliers, including Epilog Laser and Trotec, offer MOPA fiber lasers. MOPA lasers’ adjustable pulse duration makes it likely they will play a larger role in the industry in coming years.

Photo courtesy of Epilog Laser (EpilogLaser.com)

Crystal lasers?

Several solid-state lasers use crystals as their active gain medium. The most popular of these (and the one most likely to be used in materials processing) is the Nd:YAG (neodymium-doped yttrium aluminum garnet) laser. Nd:YAG lasers aren’t commonly used in the personalization industry despite being capable of engraving, marking, and cutting substrates that include some metals, ceramics, and plastics; some SSLE systems are Nd:YAG lasers.