When the Awards and Personalization Association heard about a new sublimation product that debuted in October, we wanted to know more. JDS Industries is the distributor for SubTHAT!, so we spoke with Sublimation Specialist Colin VanLint to find out more about the new product—and to see how the process works.

DIY Sublimation Blanks from JDS Industries

NEW SUBLIMATION FILM TURNS WOOD, METAL, STONE, AND MORE INTO CUSTOM SUBSTRATES

(Originally published in the November 2017 issue of Insights.)

When the Awards and Personalization Association heard about a new sublimation product that debuted in October, we wanted to know more. JDS Industries is the distributor for SubTHAT!, so we spoke with Sublimation Specialist Colin VanLint to find out more about the new product—and to see how the process works.

What does SubTHAT! sublimation film do?

VanLint: "JDS's SubTHAT! allows you to easily transform raw materials into sublimation-ready products. It is easy to apply and offers better results than spray- and liquid-application methods."

Why was this product developed?

VanLint: "SubTHAT! makes it possible to sublimate more materials, so sublimation users aren’t limited to decorating the sublimation blanks suppliers offer.

There are several hundred different sublimation substrates on the market. For someone starting with sublimation, the options look limitless. You take in all of the products you’ll be able to personalize and customize with full-cover graphics, your brain starts racing with ideas for designing and marketing each item—and stops thinking about limits.

As a sublimation specialist at JDS, I travel to trade shows to talk to people about sublimation and demonstrate the process. Inevitably, the first question I get is 'Can this be applied to anything?'

That's why I always explain that sublimation ink only adheres to substrates that have a polyurethane coating or are made from polyester fibers."

How did sublimation users react to these limits?

VanLint: "They pause to process this new boundary. That prompts the second question: 'Can I coat my own items?' Then, I have to create yet another obstacle by explaining just the difficult, time-consuming process of trying to coat your own materials for sublimation. I hated throwing a wrench into customers' creative brainstorming, but it was something I had to do. Now I can tell them to use SubTHAT! and let their creativity flourish!"

What materials can the film be used on?

VanLint: "SubTHAT! can be used on metals, ceramics, stone, glass, acrylics, and any other material that:

-

has a flat, hard, smooth surface

-

fits within your heat press and

-

can withstand temperatures up to 410° F.

Because you’re creating a custom substrate, you’ll need to experiment to find the perfect heat-press settings based on size, thickness, and composition. That's why SubTHAT! isn’t the ideal choice for creating a single item. Once you can determine the perfect settings for a given size of a material, you can use personalized art on each one to efficiently create unique, one-of-a-kind products for your customers."

How to print with a custom substrate.

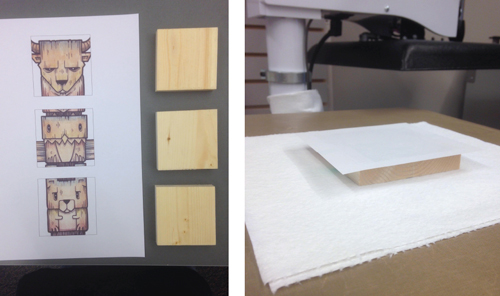

Materials Needed

-

4-in.-by-4-in. square of ¾-in.-thick wood (or use your preferred dimensions or material)

-

SubTHAT! film

-

Scissors

-

Squeegee

-

1/16-in.-thick 70A silicone sheet

-

1/8-in.-thick green heat-conductive pad

-

Sublimation transfer with artwork

Simple Steps

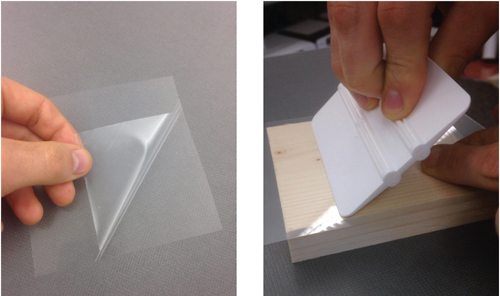

1. Cut your SubTHAT! film to your desired size. You'll want it slightly larger than the substrate for edge-to-edge coverage. Remove the slipsheet and gently use the squeegee to apply the tacky film to the raw wood, working from one edge to the other to eliminate any bubbles. The film may not be repositionable once you place it, so take care in this step.

2. Place your substrate and transfer in the heat press in this order, from bottom to top: sacrificial paper, raw wood with SubTHAT! (print side up), 1/16-in. 70A silicone sheet, and green heat conductive pad.

3. Press at 410° F for 1 minute and 45 seconds for a wood product. Your heat press time and temperature will depend on the material you're using.

4. Remove your material from the press, let it cool to room temperature, and peel away the SubTHAT! film's carrier. If the transferred film feels soft or tacky when cool or can be scratched by light pressure from a fingernail, increase your application time in 30-second increments until you get a good cure.

5. When your substrate is correctly coated with SubTHAT!, you can apply your artwork. (I repeated steps 1–4 two more times for the additional pieces of wood I needed for this project.)

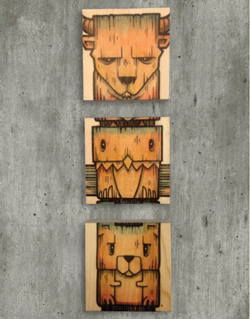

6. Press your sublimated art as you normally would, but expect some trial and error to hit the perfect heat press settings. The settings can vary greatly depending on the thickness and density of your product.

7. After pressing, remove your substrate from the press to let it cool. SubTHAT! will cure for about 24 hours following the application and sublimation processes. Then, enjoy a custom, one-of-a-kind, self-coated piece of art.

Sublimation Specialist Colin VanLint assists sublimation customers at award-winning supplier JDS Industries. Ordered in sheets or rolls, SubTHAT! is available in three formulas: gloss clear, matte clear, and matte white. With more than 17,000 products spanning the gift, awards, sign, and promotional markets, JDS is a one-stop shop for products, equipment, and supplies. To learn more, contact JDS Industries at 800.843.8853 or visit www.jdsindustries.com.