Sandcarving is a quick, clean, and simple process that will diversify any business. Sandcarving not only allows for deep

etching capabilities with sharp, clean lines, but it also offers techniques unique to sandcarving that will increase the value

of any project. These techniques include halftone, or photographic etching, frosting capabilities, complex curves, and the

popular multistage carving capability!

Master the Sandcarving 2-Step

Simplified Stagecarving? Yes, it's Possible!

By Darin Jones, Ikonics Imaging

Sandcarving is a quick, clean, and simple process that will diversify any business. Sandcarving not only allows for deep

etching capabilities with sharp, clean lines, but it also offers techniques unique to sandcarving that will increase the value

of any project. These techniques include halftone, or photographic etching, frosting capabilities, complex curves, and the

popular multistage carving capability!

Focusing on multistage carving, there’s a very simple, two-stage sandcarving process. To further simplify the procedure, we’re

using RapidMask, the only dry-process film on the market, which saves even more time and resources.

The simple steps below prove how quickly and easily a two-stage carve can be achieved on glass—and you’ll be amazed at how

one easy technique can increase the value of any project.

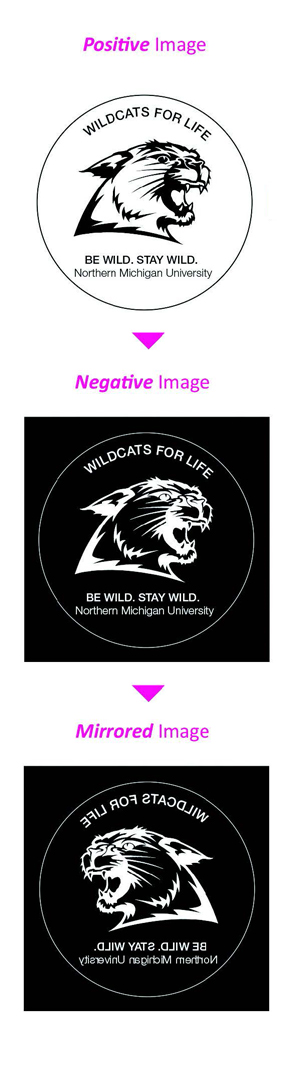

1. Generating Artwork

When it comes to any sandcarving process, optimum end results truly stem from great and accurate artwork. When working

with RapidMask and sandcarving, there are a couple important steps that MUST be addressed when creating artwork:

- Ensure the artwork is in a “negative” format. Because RapidMask is a dry-process film, the artwork must be inverted to

a negative image. Simply start creating artwork in a “positive image” format and then invert to a negative image. Once

inverted, view the artwork as the “white/clear areas = blast”! Those areas will be sandcarved and removed from the

substrate.

- If the artwork needs to be set up as a back blast, or the substrate is being sandcarved from the back side, simply mirror

the image.

- Ensure artwork is setup for a two-stage carve. There should be distinct or enclosed “islands” within the artwork. “Cut

lines” may need to be added to ensure an easy stagecarve or film removal process. Also, wide lines will help to achieve a

deep Stage One blast, which will create more separation and pop.

Before going to print, make sure the black areas are 100% black or “K” in the CMYK spectrum and the white areas are

100% white. This is extremely important because ensuring proper color levels will eliminate bad artwork prints and

prevent the film from being exposed improperly. When going to print, ensure the printing preferences are set for the

darkest, or high density, output.

2. Exposing Artwork

After the artwork is printed onto inkjet or laser

media, it’s time for exposure. We’re using the 4 mil

thickness for a deeper etch. When exposing the

artwork, make sure the artwork and RapidMask are

placed emulsion-to-emulsion. The UV light passes

through the artwork first, exposing the image onto

the film. Because we’re using RapidMask 4 mil film,

we’ll expose it between 2–2.5 minutes on a Letralite

or standard UV unit. If you’re using any other type

of UV exposure unit, a simple “snap test” can be

performed. The snap test ensures the exposed mask

is brittle enough for sandcarving.

If you’re using a different photomask, you’ll need to

wash out the film. We’re skipping that step because

we’re using a dry-process film.

3. Put Photoresist on Substrate

After the substrate is cleaned,

apply the repositionable film to

the substrate, sticky side down. A

squeegee can be utilized to apply

pressure, remove air bubbles, and

adhere the film to the substrate.

Then, simply remove the film

carrier and tape off any areas of the

substrate that need to be protected.

4. Stage one Sandcarve

After the sandcarving system is turned on and the pressure is adjusted to 40 PSI, load the substrate into the cabinet. This is

the Stage One sandcarve, the deepest carve. Thoroughly blast the entire substrate, achieving an approximate depth of ⅛ in.

deep or as deep as the line is wide. Keep the nozzle about 4–6 in. away from the substrate at a 90-degree angle. This step will

achieve the deepest etch, so keep the nozzle moving on the substrate until the desired blast depth is achieved while ensuring

the film is not compromised.

5. Remove Unwanted Photoresist

When Stage One is done, remove

the substrate from the sandcarving

cabinet. In preparation for the Stage

Two carve, peel away sections of the

remaining photoresist film. A picking

tool, razor, or even your fingernail can

help with the photoresist film removal

process.

6. Stage Two Sandcarve

The Stage Two carve can

be considered a “shotgun

blast.” The cabinet

pressure should remain

at 40 PSI. Keep 12–18 in.

between the nozzle and

the substrate; the nozzle

would be approximately at

the back of the cabinet. Be

sure the nozzle is aimed

straight at the substrate.

The shotgun blast is very

quick and simple, lasting

only a couple of seconds, to

achieve a surface etch.

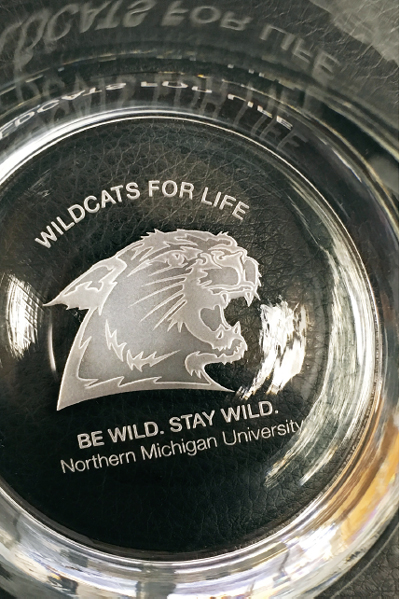

Show Off the Finished Product

Remove the entire stencil. Use warm water if needed.

Then, show off your two-step stagecarved product! This

streamlined process saves you time and labor while

creating a high-end look that will provide customers with a

variety of highly valued products

Darin Jones has been with IKONICS Imaging

for more than 13 years. As the company’s

technical training sales specialist, Jones

teaches sandcarving seminars around the

world. He holds a degree in communications

from the University of Minnesota, Duluth.

IKONICS Imaging is a “total solution”

supplier for quality sandcarving equipment

and products. Go to www.ikonicsimaging.com

to find everything you need to start and maintain your own

sandcarving business, including photoresist films, sandcarving

equipment and supplies, glass and crystal engraving products, and

training resources.