JDS Industries provides a CorelDRAW/Photo-Paint tutorial on how to fix poor-quality artwork for a personalized, laser-engraved product. See how a blurry, faded, handwritten recipe was altered in CorelDRAW and Photo-Paint before being lasered onto a bamboo cutting board to create a sentimental personalized gift.

Tutorial: Fixing Poor-Quality Artwork for Cleaner Laser Engraving

A CorelDraw/Photo-Paint Tutorial

By Shon Roti, JDS Industries

(Originally published in the April 2017 issue of Insights.)

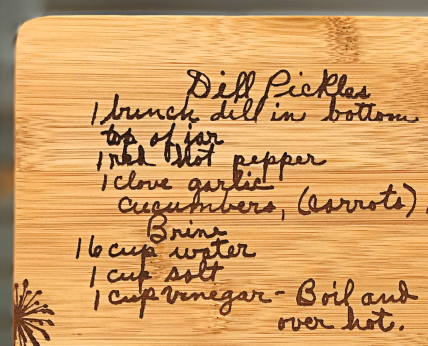

FIGURE A: The final product is a unique and personal product that anyone would be proud to display—or use daily in their kitchen!

Recently, I was discussing artwork for a project with a

JDS customer, Stacie Dannenhauer of LaserCreations.

The project involved lasering a handwritten recipe to a

bamboo cutting board. Sounds fairly straightforward, right?

However, there was an issue, and it’s one that we have all

dealt with: poor-quality artwork (the lemon).

We all know the old proverbial phrase, “If life gives you

lemons, make lemonade.” But, lemonade, of course,

requires sugar, and that is the point of the adage—you need

to take what you have and make it better. Otherwise, what

you have is just an undrinkable liquid.

The technique I shared with Stacie—and now with you—

is one that I used when I was a production artist in our

fabrication department, which I nearly had forgotten about

until we spoke.

Any version of CoreDRAW and Photo-Paint can be used

when following along with this tutorial, except the last

part, which is optional. I will be using CorelDRAW X8 and

Photo-PaintX8. This tutorial’s relevancy is not restricted

to just lasering, but it does work best with an image that

only needs to be rendered to a black and white bitmap or a

single-color vector graphic.

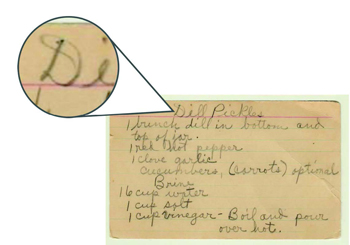

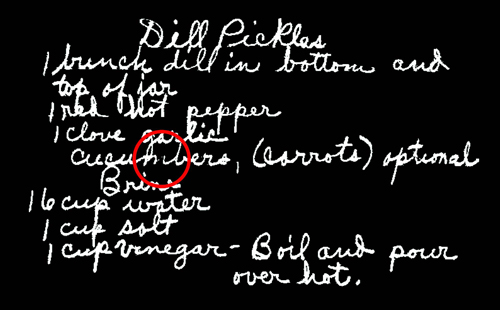

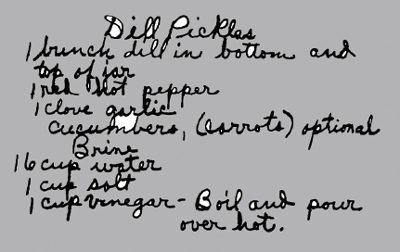

Rather than risk giving away someone else’s favorite recipe,

I’ve used my grandmother Roti’s dill pickle recipe as the

example for this tutorial. FIGURE A illustrates the end

result from this tutorial using an image that originally was scanned at 150dpi (FIGURE B). Notice the blurriness of

the handwriting in Figure B, which will look even worse

when I change it to a black and white bitmap. This is the

image that I will attempt to fix.

FIGURE B: Even magnified, handwriting on old documents such as this recipe often is barely legible and unsuitable for lasering.

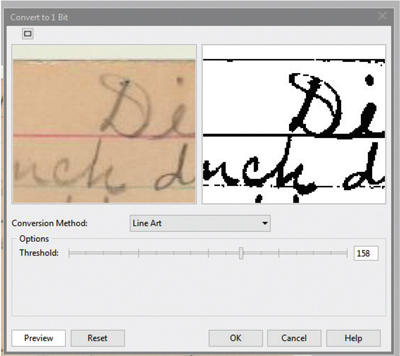

FIGURE C: After converting the image to black and white, a window enabling you to adjust the Threshold will automatically open.

FIGURE D: After adjusting the Threshold slider, the image may appear more pixilated.

In addition to the low resolution, there also is not much

contrast between the light pencil marks and the yellowed

index card, adding another level of difficulty. The focus of

this tutorial will be to add contrast, fix some trouble areas,

and smooth out the pixelated edges of this low-resolution

image without compromising the handwriting style and

readability.

I should mention that before you devote time and energy

into fixing the artwork from your customer, it may be worth

the time to ask if there is an original hard copy or a better quality

digital file that can be used. A quick e-mail or phone

call to the customer could save you a few steps.

THE PHOTO-PAINT STEPS

-

Launch Corel Photo-Paint and open the image

(Ctrl+O). If the image is in RGB, CMYK, or grayscale

mode, change the image mode to black and white

by going to Image>Convert to Black and White (1

bit). A window will open to enable you to adjust

the Threshold (FIGURE C). Zoom in closer to the

artwork by clicking on the left window. Move the

Threshold slider around until you are satisfied

with the adjustment. This step is one of the more

important adjustments, so take your time to get this

part just the way you want it. If you have the slider

too far left, much of the handwriting may disappear.

If the slider is too far to the right, unwanted pixels

will be added that you will have to clean up later.

As mentioned, the image may appear worse after

this step because of the visible pixelization that

has occurred (FIGURE D). But fear not, it will get

better.

- Next, change the mode to grayscale by going to

Image>Convert to Grayscale.

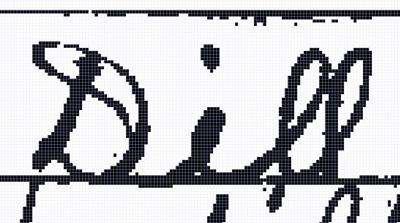

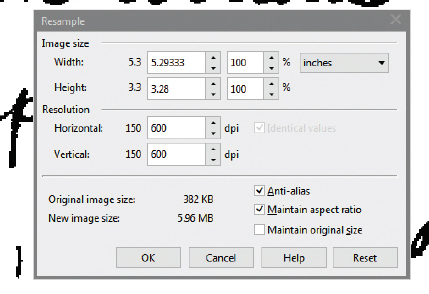

- The next step is to increase the number of pixels

in the image. Go to Image>Resample. Change the

Resolution to 600 dpi for the horizontal; the vertical

should change with it automatically (FIGURE E).

Click OK. This step does not increase the readability,

but pixels will fill in and around hard edges and offer

more data/pixels to work with for the next steps.

FIGURES F and G illustrate the letter “D” in the

artwork up close, before the resampling and after.

- Now remove any unwanted pixels from the artwork.

In this instance, I’ve decided to remove the index

card lines and some other random pixels. You can

use the Rectangle Mask tool (r) to select an area and

click the Delete button, or use the Erase tool (x) to

remove the pixels. Remember to adjust the Nib size

(brush size) as needed.

- Fix any broken or missing areas of the handwriting.

For this fix, I like to use the Eraser tool in the

negative space. Go to Image>Transform>Invert the

colors. Select the Eraser tool (x) and change the

nib size (brush size) in the Property bar. At 600

dpi, a nib size of 10 is about the same thickness

as my grandmother’s pencil point. Use this tool

to connect white areas as needed (FIGURE H).

What you choose to fix in this step is going to be a

judgement call, but don’t get too overzealous with

the Eraser tool. You’ll want to make sure it still looks

like someone else’s handwriting and doesn’t look

overcorrected. You may find that leaving some areas

unfixed helps with authenticity. I’ve chosen to fix

just enough to keep it legible.

- In the next few steps, the techniques I use will help

continue to smooth out the edges of the handwriting.

With the image still inverted in the negative, go to

Adjust>Brightness/Contrast/Intensity (Ctrl+B).

Increase the Contrast to 100% but leave the

Brightness and Intensity at 0.

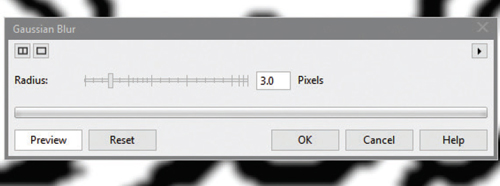

- Invert the image again and add a slight blur. Go

to Image>Transform>Invert the colors, then go to

Effects>Gaussian Blur and set the Radius to 2 or 3

pixels (FIGURE I). Click OK.

- Open Brightness/Contrast again (Ctrl +B) and

increase the contrast to 100% and slowly decrease

the Brightness to about -10. You should see the

black areas start to thicken. Now repeat this entire

step (Contrast and Brightness). The edges should appear sharper and smoother.

- Invert the image again back to the negative and blur

the image again by 2 or 3 pixels. Open Brightness/

Contrast again (Ctrl + B), increase the contrast to

100% and slowly increase the Brightness to +10.

Now you should see further improvements to the

edges of the artwork. FIGURE J illustrates the

letter “D” in the artwork at this stage of the tutorial.

- Finally, Increase the contrast by 100% and then

change the mode back to a black and white bitmap.

Go to Image>Convert to Black and White (1 bit) and

keep the Threshold slider in the middle (about 130).

Save as a TIFF or PNG file.

FIGURE E: Change the Resolution to 600 dpi; the horizontal and vertical sliders should change together automatically.

FIGURE F: The artwork before resampling.

FIGURE G: The artwork after resampling.

FIGURE H: Use the eraser tool to connect any gaps that may have been created.

FIGURE I: Add blur as shown above to help smooth out the edges of the handwriting.

FIGURE J: The edges of the artwork appear substantially smoother.

CORELDRAW STEPS

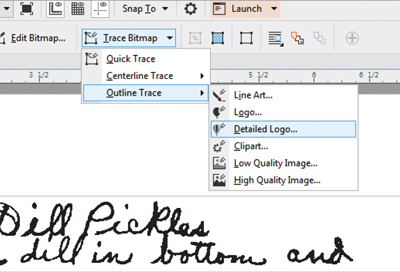

- Launch CorelDRAW and import the new file you

have created (Ctrl + I). With the bitmap selected,

launch Trace Bitmap, Detailed Logo (FIGURE K).

If you are prompted by a window that is asking

you to reduce the bitmap, click on Reduce Bitmap.

A new window will open and the rendering process

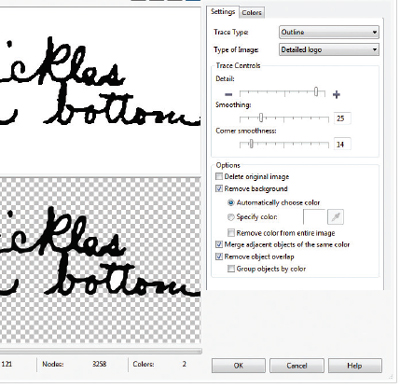

will start automatically. Generally speaking, you

will have better luck increasing the Detail to its

maximum, but keep the Smoothing and Cornering

low to maintain the details in the artwork

(FIGURE L). As an option in this window, you

can also choose to Remove Background, leaving

only the original bitmap and the vectorized

handwriting to remain. Click OK.

- Once the artwork is rendered to a vector, ungroup

the new artwork (Ctrl +U) and delete the original bitmap that is underneath.

- Select and delete any residual white areas inside

some of the letters. I’ve placed a gray box behind

the artwork to help reveal these pieces (FIGURE

M).

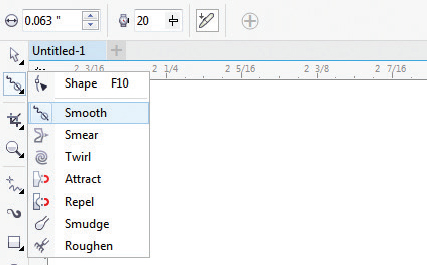

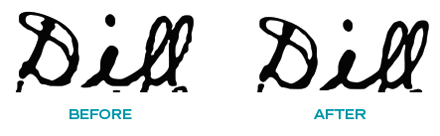

- If you have CorelDRAW X7 or X8, select the

Smooth tool located in the flyout of the Shape tool

in the Tool bar (FIGURE N).

- Choose the Nib size and Rate from the Property

bar that are small enough to affect only part of an

individual letter. A nib size of .0625 (1/16 inch)

should be about right. Set the Rate (the speed at

which changes occur) to 50 (FIGURE N).

- Click on the artwork with the Smooth tool to select

it and then click again and hold over any area that

requires flattening or smoothing. Notice the bumps

flattening out in real time. FIGURES O and P show the word "Dil" before and after using this too.

Check out the final results of this artwork lasered into a

bamboo cutting board (GFT172; FIGURE Q).

FIGURE K: Select Detailed Logo under Trace Bitmap to begin the rendering process.

FIGURE L: Adjust the Detail, Smoothing, and Cornering as needed.

FIGURE M: Be sure to select and delete residual white areas to ensure they are not marked in the final product.

FIGURE N: Set the Rate via the Property bar.

FIGURE O AND P: The word Dill before (left) and after (right) using the Smooth tool.

FIGURE Q: The final product makes a perfect gift for parents or grandparents, newlyweds, and amateur chefs and bakers alike!

IN SUMMARY

Over and over, you will find that the public has little idea

about the amount of energy, expertise, and time that

goes into their projects; they only see the end results.

In business, the recipe for success includes exceeding

expectations—and often working with a few lemons.

To view a video of this tutorial and others, go to

our YouTube channel, www.youtube.com/user/

JDSINDUSTRIES.

Shon Roti is a sublimation specialist at JDS

Industries, Inc. He has a bachelor of arts degree

from the University of Sioux Falls with an

emphasis in graphic design. He can be contacted

at shonr@jdsindustries.com. JDS Industries is a

leading supplier in the recognition and

sublimation markets. For more on JDS Industries, visit www.jdsindustries.com.